- {{ service.text }}

PhD Projects in Industry 4.0

Industry 4.0 is a popular topic in PhD research and hence we discuss about this topic in detail. Our team updates about this research field day by day. You will feel this, only when you read this blog.

Our technical team is available 24/7 for research assistance

Send your techinical enquiries directly to our technical team via mail - [email protected] or you can send it to support team via WhatsApp

PhD Projects in Industry 4.0 is a short blog that gives you about the industry 4.0 and the topics in this field. To know this, you have to get a look into this blog by now.

What is Industry 4.0?

Industry 4.0 is an advance development in the field industry with the revolution in automation. The industry 4.0 mainly focuses of all the manufacturing machineries with wireless technologies. Also this enables the use of advance techniques in machine learning, artificial intelligence, deep learning, reinforcement learning, game theory and so on.

What are new in Industry 4.0?

It is not just an update from previous version of industry 3.0 technologies, the industry 4.0 presents advances that are developed based on current industrial evolution. It understands the challenges and limitations in this field.

The field of industry 4.0 has challenges as lack of access points, not able to support large scale systems, storage of data, accuracy in the data and others. Further, the main topics in this field is given as follows.

PhD Project Topics in Industry 4.0

- Smart Manufacturing

- Blockchain Technology

- Cyber Physical System

- Redundancy Prediction and Reduction

- Supply Chain Management

- Fault Diagnosis

- Data Acquisition and Classification

- Biometric Authentication

- Task Offloading

- And Many More

Top Journal Topics in Industry 4.0

- Object Recognition and Classification

- Augmented Reality in Industrial Environment

- Smart Factory

- Cyber-Physical Production System

- Digital Twins

- Renewable Energy Generation for Industries

PhD Projects in Industry 4.0 offers you all type of help to complete your PhD in this research field. We first get all your ideas and then make sure that we move in your interest, so that it will easier for your understanding. If you don’t have know the recent topics, then you can ask us directly and select one among it.

We give you support from the selection of your topic to the end of thesis in PhD. We never compel you in selecting topic and continue all PhD with our assistance. Even you can prefer anyone service from us. Start you PhD Project with us and success will be at your hands.

Did you find it helpful ?

Leave a reply.

Free Base papers and Topics for your Research

PhD services using Research Domain with important areas

Cloud Computing with Blockchain technology for Security in PhD

Image Processing Integrates with Blockchain Technology for Security

- DSpace@MIT Home

- MIT Libraries

- Graduate Theses

Creating value with Industry 4.0

Other Contributors

Terms of use, description, date issued, collections.

Show Statistical Information

Informazioni Coronavirus

- Prospective students

- International students

- PhD candidates

- Professors and researchers

- Institutions and companies

- Career opportunities

- Research topics

- Academic Board

Industry 4.0 and Advanced Production Systems

This sub-research area focuses on advanced production systems, digitalization, and automation of manufacturing processes, with specific reference to the enabling technologies of Industry 4.0 (and subsequent paradigms).

ERC sectors

- PE8_9 Production technology, process engineering

- PE7_10 Robotics

- PE8_10 Manufacturing engineering and industrial design

- Advanced production systems

- Computerization

- Digitalization and automation

- Additive manufacturing

IEEE Account

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Distributed Information and Automation Laboratory

- Asset Management

- Automation & Control

- Data Management

- Industrial Resilience

- Intelligent Logistics

- Manufacturing Analytics

- Current Projects

- Digital Hospitals

- Completed Projects

- Digital Manufacturing on a Shoestring

- Publications

- Student Projects

- PhD Projects

- Presentations & Workshops

- Practical tools and techniques

- Industrial Advisory Board

- DIAL Newsletter

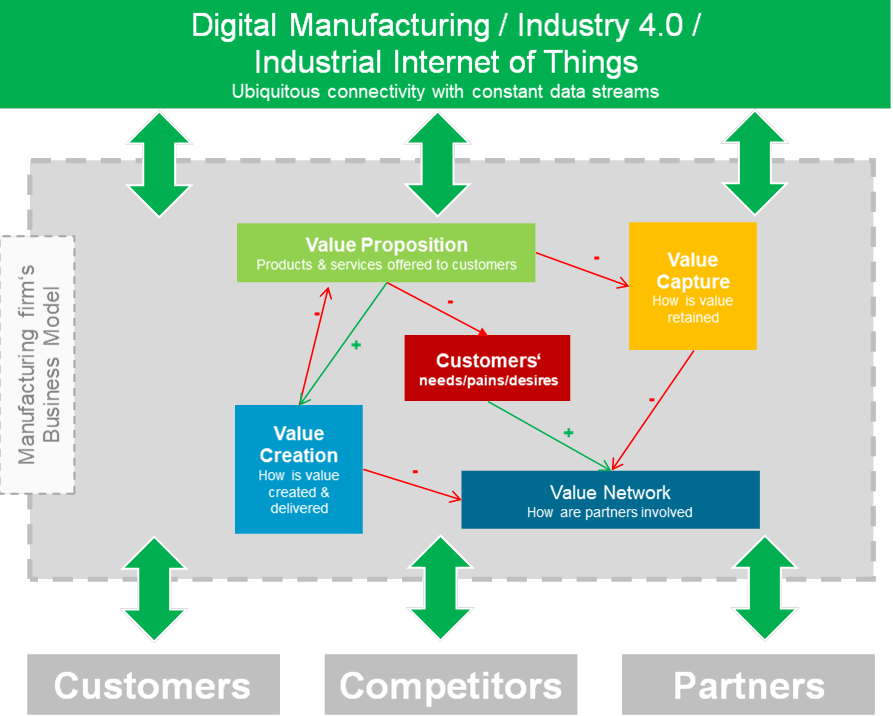

Managing Industry 4.0 holistically

The accelerated diffusion of digital technologies challenges leadership teams across all manufacturing industries. Capturing the full value of these rapid Industry 4.0 developments can only be realised by holistically orchestrating the implementation across a firm and its value network. To achieve this, it is vital for leadership teams to consider the inter-dependencies between individual activities and projects in key areas of their business, that may be as diverse as the value proposition, operational processes or value capture mechanisms – this is a complex undertaking. However, today it is not clear, how a leadership team should decide, which activities of their business model should be enhanced with which Industry 4.0 pillar and with what

Methodology

Develop a strategic decision support framework for a systematic prioritisation, which activities across a firm's business model demand 'digital' advances (including the required non-digital basics).

thyssenkrupp AG

- Institute for Manufacturing

- 17 Charles Babbage Road

- Cambridge CB3 0FS

- +44 (0)1223 766141

- [email protected]

- Site Map | Freedom of Info | Privacy

- Stay in touch:

- Artificial Intelligence

- Business Model Innovation

- Computer Aided Manufacturing

- Decision-Making for Emerging Technologies

- Design Management

- Digital Manufacturing

- Distributed Information & Automation Laboratory

- Fluids in Advanced Manufacturing

- Industrial Photonics

- Industrial Sustainability

- Inkjet Research

- Innovation and Intellectual Property

- International Manufacturing

- Manufacturing Industry Education Research

- NanoManufacturing

- Science, Technology & Innovation Policy

- Strategy and Performance

- Technology Enterprise

- Technology Management

- Service Alliance

- University Commercialisation and Innovation Policy Evidence Unit

- About IfM ECS

- Consultancy

- Professional development

- For business

- For government

- For universities

- Open courses

Department of Engineering

Accessibility | © University of Cambridge 2016

- Fully Funded PhD in Industry 4.0 and intelligent future systems

Fully Funded PhD in Industry 4.0 and intelligent future systems

University of sheffield management school.

This profile is no longer listed in the FindAPhD database and may not be available.

About the Programme

The Advanced Resource Efficiency Centre (AREC), based at Sheffield University Management School, is seeking applications for a fully funded PhD from exceptional UK/EU/International students with an outstanding academic record (distinction/high merit or equivalent), as well as a proven record in research training.

The UK Industrial Strategy has identified priority areas where capabilities in energy, self-driving automotive, food, construction, materials and manufacturing, robotics and Artificial Intelligence (AI), aviation, healthcare, battery technology and next generation services are to be supported in industry. This studentship will focus on advancing the understanding of how digitalisation transforms industry and future supply chain, investigating the transformation of future supply chain into intelligent future systems by exploring the role of Industry 4.0 and Internet of Things (IoT). How data will be valued, why ethics will be key, what social valuation are put upon disruptive digital technology, the co-existence model of man-machine to understand the future machine economy are also areas of investigation. The research will integrate management theories and apply technology advances to deliver new tools, and understand the societal and humanity implications fromthese advances. Possible projects may include:

• New business model and indicators for managing supply chains transition to Industry 4.0 and intelligent future systems (focus on global, cases include major industry from our existing network, data analytics and value assessment) • New forms of decision support methodology and tools for Industry 4.0 and intelligent future systems (focus on global, involves Microsoft) • Intelligent future systems: valuation of behavioural and social interactional management processes (focus on impact from autonomous vehicles, AI and robotics cases) • Data learning and Cloud-based intelligence sharing towards future inclusive autonomous resource management systems: a techno-societal transformation (focus on global, cases include social media type sentiment and AI for industry and management science of communication and decision, involvement of companies such as Microsoft and Amazon)

The supervisory team may include two of the following academics: Professor Lenny Koh, Dr Andrea Genovese, Dr Sonal Choudhary, Professor David Oglethorpe, Professor Andrew Simpson, Dr Erica Ballantyne, Dr Chantal Cantarelli, Dr Antonino Sgalambro, Dr Mike Simpson, Dr Rob Marchand, Dr Andrew Brint, Professor John Cullen, Professor Jonathan Linton, Dr Stuart Maguire, Professor Elaine Toms, Professor Panos Ketikidis. The selection of supervisors would depend on which project(s) is pursued and staff availability.

Application Process

Applicants should submit a 1000 word research proposal. The proposal should contain a brief background to the topic, which demonstrates knowledge of existing work in the field, and potential contributions to knowledge. It should also explain the proposed research methods and include a plan of the research, and a timeline.

Closing date for applications is 17.00 (UK time) on Friday 13 July 2018. Interviews will be held week commencing 6 August 2018

For more information and to submit an application, visit www.sheffield.ac.uk/management/study/researchdegrees/fundedprojects

Funding Notes

How good is research at university of sheffield in business and management studies.

Research output data provided by the Research Excellence Framework (REF)

Where will I study?

University of Sheffield

Our University has a reputation for world-class teaching and research excellence across a variety of disciplines. At Sheffield, you’re welcomed into a diverse, supportive community of scholars from all over the world.

Search suggestions

Based on your current searches we recommend the following search filters.

Check out our other PhDs in Sheffield , United Kingdom

Start a new search with our database of over 4,000 PhDs

PhD suggestions

Based on your current search criteria we thought you might be interested in these.

15 fully funded PhD positions in molecular technologies and systems medicine CeMM

Fully funded PhD studentships at the EPSRC Centre for Doctoral Training in Statistics and Operational Research in Partnership with Industry (STOR-i) Lancaster University

Fully Funded PhD Positions in Life Sciences - 2025 Winter Recruitment European Molecular Biology Laboratory (Heidelberg)

About the Programme

FindAPhD. Copyright 2005-2024 All rights reserved.

Unknown ( change )

Have you got time to answer some quick questions about PhD study?

Select your nearest city

You haven’t completed your profile yet. To get the most out of FindAPhD, finish your profile and receive these benefits:

- Monthly chance to win one of ten £10 Amazon vouchers ; winners will be notified every month.*

- The latest PhD projects delivered straight to your inbox

- Access to our £6,000 scholarship competition

- Weekly newsletter with funding opportunities, research proposal tips and much more

- Early access to our physical and virtual postgraduate study fairs

Or begin browsing FindAPhD.com

or begin browsing FindAPhD.com

*Offer only available for the duration of your active subscription, and subject to change. You MUST claim your prize within 72 hours, if not we will redraw.

Create your account

Looking to list your PhD opportunities? Log in here .

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > Industrial Engineering

Industry 4.0 - Current Status and Future Trends

Book metrics overview

9,696 Chapter Downloads

Impact of this book and its chapters

Total Chapter Downloads on intechopen.com

Book Citations

Total Chapter Citations

Academic Editor

Close mobile R&D

Published 25 March 2020

Doi 10.5772/intechopen.86000

ISBN 978-1-83880-094-9

Print ISBN 978-1-83880-093-2

eBook (PDF) ISBN 978-1-83880-086-4

Copyright year 2020

Number of pages 132

This book shows a vision of the present and future of Industry 4.0 and identifies and examines the most pressing research issue in Industry 4.0. Containing the contributions of leading researchers and academics, this book includes recent publications in key areas of interest, for example: a review on the Industry 4.0: What is the Industry 4.0, the pillars of Industry 4.0, current and future trends...

This book shows a vision of the present and future of Industry 4.0 and identifies and examines the most pressing research issue in Industry 4.0. Containing the contributions of leading researchers and academics, this book includes recent publications in key areas of interest, for example: a review on the Industry 4.0: What is the Industry 4.0, the pillars of Industry 4.0, current and future trends, technologies, taxonomy, and some case studies (A.U.T.O 4.0, stabilization of digitized process). This book also provides an essential tool in the process of migration to Industry 4.0. The book is suitable as a text for graduate students and professionals in the industrial sector and general engineering areas. The book is organized into two sections: 1. Reviews 2. Case Studies Industry 4.0 is likely to play an important role in the future society. This book is a good reference on Industry 4.0 and includes some case studies. Each chapter is written by expert researchers in the sector, and the topics are broad; from the concept or definition of Industry 4.0 to a future society 5.0.

By submitting the form you agree to IntechOpen using your personal information in order to fulfil your library recommendation. In line with our privacy policy we won’t share your details with any third parties and will discard any personal information provided immediately after the recommended institution details are received. For further information on how we protect and process your personal information, please refer to our privacy policy .

This book has been funded by Knowledge Unlatched. More information on this initiative can be found on http://www.knowledgeunlatched.org

Cite this book

There are two ways to cite this book:

Edited Volume and chapters are indexed in

Table of contents.

By Núbia Gabriela Pereira Carvalho and Edson Walmir Cazarini

By Jesús Hamilton Ortiz, William Gutierrez Marroquin and Leonardo Zambrano Cifuentes

By Ana Claudia Pereira Carvalho, Ana Paula Pereira Carvalho and Núbia Gabriela Pereira Carvalho

By Ercan Oztemel and Samet Gursev

By Georg Spoettl

By Felicita Chromjakova

By Vigneashwara Pandiyan and Wahyu Caesarendra

IMPACT OF THIS BOOK AND ITS CHAPTERS

9,696 Total Chapter Downloads

37 Crossref Citations

9 Web of Science Citations

73 Dimensions Citations

Order a print copy of this book

Hardcover | Printed Full Colour

Available on

Delivered by

£119 (ex. VAT)*

FREE SHIPPING WORLDWIDE

* Residents of European Union countries need to add a Book Value-Added Tax Rate based on their country of residence. Institutions and companies, registered as VAT taxable entities in their own EU member state, will not pay VAT by providing IntechOpen with their VAT registration number. This is made possible by the EU reverse charge method.

Related books

Ad hoc networks.

Edited by Jesús Hamilton Ortiz

Telecommunications Networks

Wearable technologies, mobile networks, industry 4.0.

Edited by Tamás Bányai

New Trends in the Use of Artificial Intelligence for the Industry 4.0

Edited by Luis Romeral Martinez

Industry 4.0 Transformation Towards Industry 5.0 Paradigm

Edited by Ibrahim Yitmen

Infrared Spectroscopy

Edited by Theophile Theophanides

Frontiers in Guided Wave Optics and Optoelectronics

Edited by Bishnu Pal

Abiotic Stress in Plants

Edited by Arun Shanker

Call for authors

Submit your work to intechopen.

IntechOpen Author/Editor? To get your discount, log in .

Discounts available on purchase of multiple copies. View rates

Local taxes (VAT) are calculated in later steps, if applicable.

Support: [email protected]

- Industry 4.0

- Opportunities

Activities and events

- In the media

Research opportunities

We are interested to receive applications from ambitious individuals keen to pursue research interests in Industry 4.0 at The University of Manchester. Potential PhD projects include, but are not confined to, the following:

- The use of AI to achieve real time optimisation of legacy systems

- Augmented Reality (AR): AR assisted assembly of flat-pack flexible assembly stations

- Biologicalisation of manufacturing

- Injection mould 4.0

- Mobile robots for additive manufacturing

- Three-axial additive manufacturing

- Digital-twin-assisted machining monitoring

- Cloud-based monitoring of machining chatter

- Fault simulation and diagnosis of feed drivers

- Non-verbal communication with machine tool

- Virtual simulation and optimisation of extrusion-based additive processes

- Virtual modelling of near-field electrospinning

- Modelling and control of laser surface texturing

- Digitised manufacturing chain in the shop floor

- Tool wear monitoring by feed drive currents.

Alternatively follow the link below to use FindaPhD for funded opportunities:

Use FindaPhD’s filters to discover funded PhD projects that align with MACE’s areas of expertise.

Funding and further enquiries

Various sources of PhD funding are also available.

For more information on PhD project topics available that may be developed further in discussion with academics to align with your interests and expertise please see individual staff pages .

For general queries about funding and how to apply please contact the Student Recruitment and Admissions Team .

Martin Lockey Senior Postgraduate Admissions Administrator George Begg Building – B15 0161 275 4345 [email protected]

Innovate UK

Driving growth by working with companies to de-risk, enable and support innovation.

Past seminars, conferences and future events from the Industry 4.0 research group.

+44 (0) 161 306 6000

The University of Manchester Oxford Rd Manchester M13 9PL UK

Connect with us

Mechanical, Aerospace and Civil Engineering, The University of Manchester

Industry 4.0 Driven Manufacturing Technologies

- © 2024

- Ajay Kumar ORCID: https://orcid.org/0000-0001-7306-1902 0 ,

- Parveen Kumar ORCID: https://orcid.org/0000-0002-2922-6228 1 ,

- Yang Liu ORCID: https://orcid.org/0000-0001-8006-3236 2

Department of Mechanical Engineering, JECRC University, Jaipur, India

You can also search for this editor in PubMed Google Scholar

Mechanical Engineering, Rawal Institute of Engg. & Technology, Faridabad, India

Dept of Management and Engineering, Linköping University, Linköping, Sweden

- Provides case studies showing solutions from industry and society

- Integrates Industry 4.0 tools, e.g., digital twins, artificial intelligence, nature-inspired algorithms, and the IoT

- Bridges the gap between R&D in human-machine interaction for manufacturing and practical application

Part of the book series: Springer Series in Advanced Manufacturing (SSAM)

This is a preview of subscription content, log in via an institution to check access.

Access this book

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as EPUB and PDF

- Read on any device

- Instant download

- Own it forever

- Durable hardcover edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Other ways to access

Licence this eBook for your library

Institutional subscriptions

About this book

This book is a comprehensive guide to the latest advancements in manufacturing, adopting an Industry 4.0 approach. It covers the core principles of big data informatics, digital twin technology, artificial intelligence, and machine learning strategies. Readers will gain insights into the realm of cyber-physical intelligent systems in production, the role of blockchain, and the significance of information and communication technology.

With a focus on real-time monitoring and data acquisition, the book offers practical solutions for online error troubleshooting in manufacturing systems. It explores a wide range of Industry 4.0-based applied manufacturing technologies and addresses the challenges posed by the dynamic market of production.

Recognizing the lack of a cohesive resource on manufacturing advancements within the context of Industry 4.0, the authors have taken the initiative to compile this valuable knowledge from domain experts. Their goal is to disseminate these insights with this book.

The book will be beneficial to various stakeholders, including industries, professionals, academics, research scholars, senior graduate students, and those in the field of human healthcare. With its comprehensive coverage, the book is an important reference for technical institution libraries and a useful reader for senior graduate students.

- Intelligent Manufacturing

- Industry 4.0

- Digital Twin

- Artificial Intelligence

- Internet of things

- Cyber-Physical Production System

- Cloud Manufacturing

- Cybersecurity

- Internet-based manufacturing

Table of contents (18 chapters)

Front matter, evolution of digital twin in manufacturing application: definition, architecture, applications, and tools.

- Suveg V. Iyer, Kuldip Singh Sangwan, Dhiraj

Intelligent Feature Engineering for Monitoring Tool Health in Machining

- Debasish Mishra, Krishna R. Pattipati, George M. Bollas

Experimental Investigation of Process Parameters Effects on Extrusion Blow Molding Process Using Response Surface Methodology for Industry 4.0

- Rajendra Shimpi, Chandrakant Wani, Rakesh Chaudhari, Sarvoday Joharapurkar, Hargovind Soni, Ajay Kumar

Finite Element Analysis and Experimental Investigation of 3D Printed Biomimetic Structures

- D. L. Belgin Paul, Ayyappan Susila Praveen, V. Loganathan

Industry 4.0 in Aircraft Manufacturing: Innovative Use Cases and Patent Landscape

- Vineet Bhatia, Ajay Kumar, Sumati Sidharth, Sanjeev Kumar Khare, Surendra Chandrakant Ghorpade, Parveen Kumar et al.

Comparative Multi-criteria-Decision Making Approach for the Optimization of Abrasive Water Jet Machining Process Parameters Using MABAC

- Bimal Tamang, Satyam Sharma, Soham Das, Spandan Guha, Ajay Kumar, Ranjan Kumar Ghadai

An Empirical Analysis of Factors Influencing Industry 4.0 Implementation in Manufacturing SMEs

- Malika Aitzhanova, Dinara Dikhanbayeva, Ali Turkyilmaz, Essam Shehab

A Cost-Minimization Approach to Production and Maintenance Planning Considering Imperfect Repairs and Human Resource Constraints

- Taha-Hossein Hejazi, Donya Ramezani, Ali Golestanian

Environment-Friendly Practices for Integrating Green Business with Green Supply Chain Management: Industry 4.0 Perspectives and Beyond

- B. K. Mawandiya, Aditya Choksi, Anjaney Lokapur, Ajay Kumar, M. A. Makhesana, K. M. Patel et al.

Barrier Analysis for the Sustainable Business Practice of a Textile and Apparel Industry in Fiji Using an ISM Approach

- D. Seenivasagam, R. Ananthanarayanan, A. K. Jeevanantham, P. Kumar

Strategic Design Optimization of Cutting Tools for Enhanced Manufacturing Efficiency

- Abhishek Agarwal, Parveen Kumar, Ajay Kumar, Ranjan Kumar Ghadai

Exploring the Challenges of Integrating Lean Green Practices in Industry 4.0 Manufacturing Frameworks: An Empirical Study

- Rajesh Kumar, Rajender Kumar, Ashwini Kumar

Robotic Arm 3D Printing: Technological Advancements and Applications

- Sourabh Anand, Gayatri, Manoj Kumar Satyarthi, Pushpendra S. Bharti, Ajay Kumar, Sarita Rathee

Elephant Swarm Water Search Algorithm-Based Optimization of a Laser Beam Machining Process

- Sunny Diyaley, Shankar Chakraborty, Ajay Kumar, Kanak Kalita

Progressive Automation: Mapping the Horizon of Smart Manufacturing with RoboDK Workstations and Industry 4.0

- Mukul Kumar, Sourabh Anand, Pushpendra S. Bharti, Manoj Kumar Satyarthi, Parveen Kumar, Ajay Kumar

Improvising the Quality of Manifold Production Using Six-Sigma Technique for Implementation in Automobile Manufacturing Industries: A Case Study

- Sachin Kumar, Aman Kumar, Ajay Kumar

Digital Twin Integration for Enhanced Control in FDM 3D Printing

- Sourabh Anand, Manoj Kumar Satyarthi, Pushpendra S. Bharti, Parveen Kumar, Ajay Kumar

Intelligent Manufacturing in Aerospace: Integrating Industry 4.0 Technologies for Operational Excellence and Digital Transformation

- Vineet Bhatia, Sumati Sidharth, Sanjeev Kumar Khare, Surendra Chandrakant Ghorpade, Parveen Kumar, Ajay Kumar et al.

Editors and Affiliations

Mechanical engineering, rawal institute of engg. & technology, faridabad, india.

Parveen Kumar

About the editors

Prof. Ajay Kumar is currently serving as a Professor in Department of Mechanical Engineering, School of Engineering and Technology, JECRC University, Jaipur, Rajasthan, India. He received his Ph.D. in the field of Advanced Manufacturing from Guru Jambheshwar University of Science & Technology, Hisar, India after B.Tech. (Hons.) in mechanical engineering and M.Tech. (Distinction) in manufacturing and automation. His areas of research include Incremental Sheet Forming, Artificial Intelligence, Sustainable Materials, Additive Manufacturing, Mechatronics, Smart Manufacturing, Industry 4.0, Waste Management, and Optimization Techniques. He has over 140 publications in international journals of repute including SCOPUS, Web of Science and SCI indexed database and refereed international conferences. He has also co-authored and co-edited more than 20 books and proceedings with ELSEVIER, Springer, CRC Press, WILEY, De Gruyter, IOP, AIP and IGI Global. He has organized various national and international events including an International conference on Mechatronics and Artificial Intelligence (ICMAI-2021), International conference on Artificial Intelligence, Advanced Materials, and Mechatronics Systems (AIAMMS-2023) as conference chair. He has more than 20 national and international patents to his credit. He has supervised more than 8 M.Tech, Ph.D scholars and numerous undergraduate projects/ thesis. He has a total of 15 years of experience in teaching and research. He is Guest Editors and Review Editor of the reputed journals including Frontiers in Sustainability. He has contributed to many international conferences/ symposiums as a session chair, expert speaker, and member of the editorial board. He has won several proficiency awards during the course of his career, including merit awards, best teacher awards, and so on. He is adviser of QCFI, Delhi Chapter student cell at JECRC University and has also authored many in-house course notes, lab manuals, monographs and invited chapters in books. He has organized a series of Faculty Development Programs, International Conferences, workshops, and seminars for researchers, PhD, UG and PG level students. He is associated with many research, academic, and professional societies in various capacities. ORCID ID: https://orcid.org/0000-0001-7306-1902

Parveen Kumar is currently serving as an Assistant Professor and Head in Department of Mechanical Engineering at Rawal Institute of Engineering and Technology, Faridabad, Haryana, India. He has submitted Ph.D. from National Institute of Technology, Kurukshetra, Haryana, India. He completed his B.Tech. (Hons.) from Kurukshetra University, Kurukshetra, India and M.Tech. (Distinction) in Manufacturing and Automation from Maharshi Dayanand University, Rohtak, India. His areas of research include Intelligent Manufacturing Systems, Materials; Die less Forming, Design of Automotive systems, Additive Manufacturing, CAD/CAM and Artificial Intelligence, machine learning and Internet of Things in manufacturing, multi objective optimization techniques. He has over 50 publications in international journals of repute including SCOPUS, Web of Science and SCI indexed database and refereed international conferences. He has 8 national and international patents in his credit. He has supervised 2 M.Tech. scholars and numerous undergraduate projects/theses. He has a total of 13 years of experience in teaching and research. He has co-authored/co-edited several books with ELSEVIER, CRC Press, WILEY, De Gruyter and IGI Global. He is also book series editor of “Industrial and Manufacturing Systems and Technologies: Sustainable and Intelligent Perspectives” in CRC Press, Taylor and Francis. He has organized a series of Faculty Development Programmes, workshops, and seminar for researcher, UG level students. ORCID ID: https://orcid.org/0000-0002-2922-6228

Dr. Yang Liu received the M.Sc. (Tech.) degree in telecommunication engineering and D.Sc. (Tech.) degree in industrial management from the University of Vaasa, Finland, in 2005 and 2010, respectively. He is currently a tenured Associate Professor and Doctoral Supervisor with the Department of Management and Engineering, Linköping University, Sweden; a Visiting Faculty with the Department of Production, University of Vaasa, Finland; and a Chair Professor with Jinan University, China. Meanwhile, he is an Adjunct/Visiting Professor at multiple other universities. His research interests include sustainable smart manufacturing, product service innovation, decision support system, competitive advantage, control systems, autonomous robots, signal processing, and pattern recognition. Prof. Liu has authored or co-authored more than 130 peer-reviewed scientific articles and is ranked No.1 among the top authors on “big data analytics in manufacturing”. His publications have appeared in multiple distinguished journals, and some ranked as top 0.1% ESI Hot Papers and top 1% ESI Highly Cited Papers. He serves as an Associate Editor of the prestigious Journal of Cleaner Production and Journal of Intelligent Manufacturing, referees in over 60 SCI leading journals, and external reviewer for NSERC of Canada and CONICYT of Chile.

Bibliographic Information

Book Title : Industry 4.0 Driven Manufacturing Technologies

Editors : Ajay Kumar, Parveen Kumar, Yang Liu

Series Title : Springer Series in Advanced Manufacturing

DOI : https://doi.org/10.1007/978-3-031-68271-1

Publisher : Springer Cham

eBook Packages : Engineering , Engineering (R0)

Copyright Information : The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG 2024

Hardcover ISBN : 978-3-031-68270-4 Published: 14 September 2024

Softcover ISBN : 978-3-031-68273-5 Due: 28 September 2025

eBook ISBN : 978-3-031-68271-1 Published: 13 September 2024

Series ISSN : 1860-5168

Series E-ISSN : 2196-1735

Edition Number : 1

Number of Pages : XXI, 434

Number of Illustrations : 14 b/w illustrations, 130 illustrations in colour

Topics : Industrial and Production Engineering , Artificial Intelligence , Cyber-physical systems, IoT , Professional Computing , User Interfaces and Human Computer Interaction , Computational Intelligence

- Publish with us

Policies and ethics

- Find a journal

- Track your research

Calibrating the PhD for the Industry 4.0: global concerns, national agendas and Australian institutional responses

- Policy Reviews in Higher Education 3(3):1-22

- Deakin University

- RMIT University

Discover the world's research

- 25+ million members

- 160+ million publication pages

- 2.3+ billion citations

No full-text available

To read the full-text of this research, you can request a copy directly from the authors.

- Nurizal Dwi Priandani

- Raquel María Pérez-García

- Abbe Winter

- Brendah Kembabazi

- Zaharah Salwati Baba

- Rhonda Boorman

- Georgi Cohen

- Hanna Suominen

- Richard Budd

- Chathuri Gunarathna

- Rebecca Yang

- Pabasara Wijeratne Mudiyanselage

- Sujan Dev Sureshkumar Jayakumari

- Kunnumpurath Bijo

- Narelle Campbell

- Tebeje Molla

- Joey V Barnett

- Allen Consulting Group

- Int J Acad Dev

- George E. Walker

- Laura Jones

- Catherine Manathunga

- Rachael Pitt

- Kim Khim Tan

- STUD HIGH EDUC

- Kathleen Densmore

- Jeremy Rifkin

- Claudia Goldin

- Lawrence F. Katz

- Thomas Piketty

- Chris Woolston

- CLAUDIA GOLDIN

- Klaus Schwab

- Denise Cuthbert

- Leul Tadesse Sidelil

- James J. Heckman

- Bryan Caplan

- Susanne Schmidt

- Peter James Bentley

- Pol Futures Educ Internet

- Kirsty Whitman

- TECHNOL FORECAST SOC

- M. V. Heitor

- John Vaizey

- T. W. Schultz

- Carl Benedikt Frey

- Michael A. Osborne

- Amartya Sen

- Wendy Brown

- J. R. Bjerklie

- Robin Usher

- Gail Craswell

- Stud Cont Educ

- Kay M. Harman

- Grant Harman

- Fazal Rizvi

- Recruit researchers

- Join for free

- Login Email Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google Welcome back! Please log in. Email · Hint Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google No account? Sign up

Smart. Open. Grounded. Inventive. Read our Ideas Made to Matter.

Which program is right for you?

Through intellectual rigor and experiential learning, this full-time, two-year MBA program develops leaders who make a difference in the world.

Earn your MBA and SM in engineering with this transformative two-year program.

A rigorous, hands-on program that prepares adaptive problem solvers for premier finance careers.

A 12-month program focused on applying the tools of modern data science, optimization and machine learning to solve real-world business problems.

Combine an international MBA with a deep dive into management science. A special opportunity for partner and affiliate schools only.

A doctoral program that produces outstanding scholars who are leading in their fields of research.

Bring a business perspective to your technical and quantitative expertise with a bachelor’s degree in management, business analytics, or finance.

Apply now and work for two to five years. We'll save you a seat in our MBA class when you're ready to come back to campus for your degree.

Executive Programs

The 20-month program teaches the science of management to mid-career leaders who want to move from success to significance.

A full-time MBA program for mid-career leaders eager to dedicate one year of discovery for a lifetime of impact.

A joint program for mid-career professionals that integrates engineering and systems thinking. Earn your master’s degree in engineering and management.

Non-degree programs for senior executives and high-potential managers.

A non-degree, customizable program for mid-career professionals.

New MIT Sloan courses prioritize AI, analytics, and climate

GDPR reduced firms’ data and computation use

23 MIT startups to watch in 2024

Credit: Seita / Shutterstock

Ideas Made to Matter

Manufacturing

How to forge a clear path to Industry 4.0

Beth Stackpole

Oct 12, 2022

Manufacturers are counting on technologies and systems known collectively as Industry 4.0 to drive efficiencies and unleash new revenue streams in their sectors. Industry 4.0 leverages sensor technologies, advanced analytics, artificial intelligence, and machine learning capabilities to collect and analyze data.

Benefits include reducing production downtime, improving product quality, and enabling proactive maintenance.

But important factors, including legacy operations and failure to effectively engage frontline workers in operational redesign, often stand in the way of such large-scale transformation.

Momentum for Industry 4.0 is growing — one report by Statista projects the market will swell from $263 billion in 2021 to $1.1 trillion by 2028.

Interest is surging, in part, because sensor networks are the backbone for creating feedback loops to identify hidden factories , the poorly understood processes and workarounds that drive up production costs and slow systems down.

Spending on Industry 4.0 will swell from $263 billion in 2021 to $1.1 trillion by 2028.

Yet as organizations roll out Industry 4.0, they often end up collecting data at a much faster rate than it can be utilized, according to MIT Sloan senior lecturer John Carrier.

Carrier, who teaches the MIT executive education course “ Implementing Industry 4.0: Leading Change in Manufacturing and Operations ,” argues that the biggest impediments to Industry 4.0 transformation are operations practices and legacy mindsets that keep employees tethered to familiar work patterns, despite investment in new technologies and business process innovations.

Among the core challenges are:

Lack of standardization. There are too many variations in the old ways of working, which make it difficult to discover the business processes and workflows that will reduce business risk and improve productivity.

Ghosts of old technology. When new technologies and ways of working present a challenge, some employees will go back to what is familiar. Until employees develop confidence in the new technology, they will revert to the old system when put under pressure. Value is not realized until the old ways of working are phased out.

Insufficient preparation. Companies that invest in the latest sensors and advanced software often underestimate the level of workforce training required to use those tools to improve maintenance and diagnostics. Capital-intensive systems require more preparation — the level of preparation and training should be matched to the complexity of the machinery.

A blueprint for transformation

Based on experience with industrial clients, Carrier has formulated a blueprint to avoid the trap of purchasing technology that is underutilized or doesn't deliver the intended business outcomes. He advocates for a more measured transition process that draws on systems thinking and addressing cultural norms.

This will scope lofty Industry 4.0 visions into practical strategies and manageable next steps designed to improve internal processes. Key steps include:

Focusing on critical but manageable problems that will drive initial stages of transformation. Manufacturers often install networks comprised of hundreds of sensors and only then circle back to solve a specific problem. Technology does not make problems disappear. In fact, technology can exacerbate problems by creating data overload and eroding employees' trust in the new system.

“Wiring up and fixing five pieces of equipment instead of initially wiring up 500 can be advantageous,” Carrier said. “Otherwise, you risk spending 12 to 18 months on data warehousing, sensor calibration, and maintenance before realizing improvements in performance.”

Instead of launching a full-scale network with hundreds of sensors, Carrier recommends a moderated approach that pinpoints a specific problem and harnesses Industry 4.0 capabilities to solve it. Engaging employees to reveal critical stress points in their jobs and evaluating processes to identify opportunities for improvement and value creation is essential for broader transformation.

“The system is trying to tell you where it needs help,” Carrier said. “You have to learn to listen to the system to determine where sensors are needed. Use technology to help see what is missing and engage your operators in problem-solving.”

Start with “seeing” the missing feedback loops. Knowing where to establish a feedback loop is critical to Industry 4.0’s business value, but the question is where to start. The search for hidden factories can be fertile ground, as this exercise presents an opportunity to listen to the system and identify the largest gaps. It is also important to put processes in place that reduce the time from measurement to action. Collecting data that sits in a database or spreadsheet is insufficient to drive change.

For example, Heineken Mexico applied learning from this approach to solve a bottleneck at its production plant .

Sequence in technology adoption while removing unsustainable current systems. Deploying new technologies like sensors, cloud platforms, and advanced algorithms can empower workers with new insights. But as soon as they run into problems or encounter systems that are complex and unwieldy, they are going to revert to old systems and traditional ways of working.

By introducing tightly scoped and incremental Industry 4.0 initiatives, workers can more easily digest new systems and adjust to new work patterns. At the same time, it is important to remove old systems to eliminate fallback possibilities. Subtraction is harder than addition, and leaders must provide the space and time for their employees to incorporate the new technology and redesign their work.

Executive education Dec 12 – 14 2022: Implementing Industry 4.0

Related Articles

PROFESSIONAL CERTIFICATE PROGRAM IN

Industry 4.0, the path to success in the 4th industrial revolution.

Organizations operate in an environment that is technologically and competitively evolving more rapidly than ever before. As such, they continue to redesign their product operations, business models, and customer support solutions. Until now, industry has sought profitability in standardization, series production, large volumes, and cost reduction.

Now, organizations must adjust to this disruptive market leveraging technology to drive growth and efficiency. New technologies are a game-changer, as they allow greater product customization breaking fixed structures from factories, making products more modular, and generating profits despite producing fewer products.

Organizations that engage in intense management practices and technology deployment can improve asset efficiency by 10-20%.

Source: Deloitte analysis

Additive manufacturing (processes that make three-dimensional products from a digital design) can reduce material costs by up to 90% and energy costs by up to 50%.

Source: World Economic Forum

The use of integrated processes in healthcare systems in an economy of scale enables cost reduction by 15-30%.

Source: Strategy& PWC

An online Professional Certificate Program to boost performance through disruption

From leading technologies such as the internet of things (IoT) and artificial intelligence to understanding the fundamentals of smart manufacturing and product platforms, through the Professional Certificate Program in Industry 4.0, we prepare professionals to tackle these challenges head-on and provide them with the knowledge and tools to succeed in the digital age.

The objective? To help them bring to their organizations:

Greater Efficiency by learning how to optimize product processes

Maximum Impact by learning about technology management

In this tailored program, participants will be able to learn about the technologies and tools most applicable in today’s industry directly from leaders in the sector who are pioneering change.

LEARN MORE ABOUT THE PROGRAM SPECIFICS

The learning journey.

For twelve months, and in a completely online format, we guide participants through the five courses that will influence and help them carry out their own industrial revolution:

Management of Technology II: Strategy & Portfolio Analysis

- Machine Learning: From Data to Decisions

- Digital Platforms: Designing Two-Sided Markets from APIs to Feature Roadmaps

Forecasting Technology Innovation: Using Data for Strategic Advantage

Leadership & Innovation

- Women in Leadership: Becoming an Agent of Change

The skills you will develop

By studying and passing the five courses that are part of the Professional Certificate in Industry 4.0, you will be able to develop:

Understand the evolution of the industry

from craft manufacturing to mass customization.

Leverage platforms for identifying new market

and product opportunities to generate revenue growth.

Identify major contemporary methods

and tools for product family and platform design.

Explore emerging trends in smart manufacturing

and visualize production data to better understand key variables and underlying phenomena in a manufacturing environment.

Delve deeper into machine innovation and machine vision,

working through different iterations of a fiber extrusion device (FrED), specifically designed to provide program participants examples of how to optimize machines.

Carry out advanced data analysis

using data sets produced on FrED in a manufacturing setting.

Apply the theory behind the IoT+

to construct real applications and improve them using smart technologies.

Learn to quantify technological progress over time

using relevant figures of merit (FOMs), and map one or more technologies to a target product and/or service of their choice and set realistic FOM-based targets.

Develop strategies, cultures, and structures

from a leadership perspective that foster creativity and innovation.

In addition, you will receive a Certificate of Completion

All the participants who successfully complete Industry 4.0 will recieve a Certificate of Completion from MIT Professional Education. Furthermore, the participants who complete the program recieve Continuing Education Units (CEUs)*.

To obtain CEUs, complete the accreditation confirmation, which is available at the end of the course. CEUs are calculated for each course based on the number of learning hours.

* The Continuing Education Unit (CEU) is defined as 10 contact hours of ongoing learning to indicate the amount of time they have devoted to a non-credit/non-degree professional development program.

To understand whether or not these CEUs may be applied toward professional certification, licensing requirements, or other required training or continuing education hours, please consult your training department or licensing authority directly.

This Professional Certificate Program is aimed at

- PLANT MANAGERS and Product managers.

- PRODUCT LINE STRATEGISTS, PLATFORM ARCHITECTS, R&D engineers, and systems engineers in industrial and government contexts.

- DESIGN AND MANUFACTURING ENGINEERS seeking to learn about data and modeling in a manufacturing environment.

- DATA SCIENTISTS looking to apply their craft to the growing field of smart manufacturing.

- CONSULTANTS who want to add value around the latest technology transformations in manufacturing.

A CLOSER LOOK AT THE PROFILE

- Professionals who want to obtain a broader strategic vision about how methodologies, technologies and tools can transform their operations.

- Also, those who are interested in understanding how to define modular and scalable product architectures, utilizing standardization, customization, and platform leveraging strategies to maximize cost savings.

Meet the instructors of this program

Listed in alphabetical order .

DIRECTOR OF THE MIT MASTER OF ENGINEERING IN ADVANCED MANUFACTURING AND DESIGN. ASSOCIATE DIRECTOR, MIT.NANO.

Dr. brian w. anthony.

"Using technology to refine the manufacturing process allows us to offer better products in the market, faster and more economically".

Dr. Anthony is director of the MIT Master of Engineering in Manufacturing Program, co-director of the Medical Electronic Device Realization Center and deputy director of the MIT Skoltech Initiative. He possesses more than 20 years of product realization experience and has won an Emmy from the Academy of Television Arts and Sciences for his innovations in broadcast technology. Dr. Anthony designs instruments and techniques to monitor and control physical systems. His work involves the analysis and the design of systems. He also uses mechanical, electrical and optical engineering as well as computer science and optimization to develop solutions.

Dr. Anthony´s research revolves around the design of instruments and techniques for measuring and controlling complex physical systems and includes the development of instruments and measurement solutions for manufacturing, medical diagnostics, and imaging diagnostics. In addition to his academic work, he has extensive experience in market-driven technological innovation, product development and entrepreneurship, and marketing at the point where information technology and advanced manufacturing come into contact. As a teacher, his main interests are the modeling of large-scale systems in a variety of areas involving decision making and the development of optimization algorithms and software useful for analyzing and designing these types of systems. He is an expert in market-driven technological innovations, as well as in entrepreneurship.

DIRECTOR, SYSTEM ARCHITECTURE GROUP AT MIT

Dr. bruce cameron.

"Digital platforms are some of the most interesting (and hardest!) technical challenges to work on today."

Dr. Bruce Cameron is director of the System Architecture Lab at MIT and co-founder of the consulting firm Technology Strategy Partners. His areas of research include technology strategy, system architecture and product platform management. Previously, Dr. Cameron led the “MIT Commonality”, a research study of 30 companies on platform performance, which concluded that companies face systemic pressure on homogeneity, in part, as a result of problems in determining costs. Dr. Cameron has supervised more than 50 graduate students and conducted research projects for Amazon, BP, Sikorsky, Nokia, Caterpillar, AMGEN, Verizon and NASA.

Dr. Cameron teaches the subject of System Architecture for the “System Design and Management”, where he has trained over 500 students. Dr. Cameron´s teaching at Sloan Executive Education has been rated as the highest level of Executive Education program at MIT for several years. In addition, he is the Faculty Director of MIT´s online certificate “Architecture and System Engineering”, which has trained more than 5,300 participants.

PROFESSOR OF AERONAUTICS, ASTRONAUTICS AND SYSTEMS ENGINEERING AT MIT

Prof. olivier de weck.

"The design of platforms and product families is aimed at achieving long-term success and survival of companies".

Olivier de Weck was born in Switzerland and has a degree in industrial engineering from the ETH Zurich and in aerospace systems engineering from MIT. Prior to joining MIT, he was an engineering liaison and later director of the McDonnell Douglas F/A-18 aircraft engineering program.

Professor De Weck is a leader in systems engineering research. He focuses on the design of complex man-made systems, such as aircraft, spacecraft, cars, printers and critical infrastructure, and on their evolution. His main focus is on strategic properties that have the potential to maximize life cycle value. Since 2001, his group has developed new methods and quantitative tools that explicitly consider production, flexibility, common features and sustainability, among other characteristics. Professor De Weck’s teaching emphasizes excellence, innovation, and the combination of theory and practice.

SENIOR LECTURER IN THE DANIEL J. RICCIO GRADUATE ENGINEERING LEADERSHIP PROGRAM AT MIT

Dr. david niño.

"Leaders learn to find important problems but define them in such a way that allows a team to come together to solve them".

EXECUTIVE DIRECTOR OF MIT'S GEOSPACIAL DATA CENTER

Dr. abel sanchez.

"Five technologies are redefining both the way we make our products and the types of opportunities that exist in the marketplace".

Dr. Sanchez is the architect of the global network “The Internet of Things” and data analysis platforms for SAP, Ford, Johnson & Johnson, Accenture, Shell, Exxon Mobil and Altria. In cyber security, he has developed cyber-attack impact analyses for the U.S. Department of Defense and a password firewall for the IARPA.

Dr. Abel Sanchez holds a PhD from the Massachusetts Institute of Technology (MIT) and teaches MIT courses in cyber security, engineering, blockchain and data science. He has been involved in developing educational software for Microsoft and establishing the Accenture Technology Academy. He has produced over 150 educational videos, has 10 years of experience with learning management systems and has made deployments in the Americas, Asia and Europe.

PROFESSOR OF MECHANICAL ENGINEERING AND INDUSTRIAL ENGINEERING

Prof. timothy w. simpson.

"Courses often don’t ask the question,‘How can we really design and take advantage of these processes?’ and that question drives my courses."

Timothy W. Simpson is a professor of mechanical and industrial engineering at Pennsylvania State University. He holds senior positions in technical design and in the Faculty of Information Science and Technology. His research areas include product family design and platform-based product development, multidisciplinary design optimization, commercial space exploration, and additive manufacturing. He has published over 250 articles in peer-reviewed journals and conference proceedings. He is the senior editor of two books, ‘Product Platform and Product Family Design: Methods & Applications’ (2005) and ‘Advances in Product Family and Product Platform Design: Methods & Applications’ (2013). His research has been supported by federal and state agencies such as NSF, ONR, DARPA, EDA and DCED, as well as numerous companies ranging from startups to multinationals.

He has worked with more than 30 different companies to apply his methods of product line improvement and product development practices. He helped establish and manage the Product Platform group on LinkedIn.

DIRECTOR OF THE MIT GEOSPATIAL DATA CENTER

Prof. john r. williams.

"Once you climb that first mountain of knowledge, you will be able to teach yourself many things".

Professor John R. Williams’ research focuses on the development and application of computing algorithms in distributed cyberphysical systems. He was director of the Auto-ID Laboratory, where the Internet of Things was invented. He is considered, along with Bill Gates and Larry Ellison, one of the 50 most powerful people in “Computer Networks”.

He is author and coauthor of more than 250 articles in journals and conferences. Professor Williams teaches courses on the basics of programming, modern software development, the architecture of web, cloud and blockchain systems. In addition, he holds a BSc in Physics from Oxford University, an MSc in Physics from UCLA, and a PhD from the University of Swansea.

JOHN E. BURCHARD PROFESSOR OF HUMANITIES AND CO-CHAIR OF THE GENDER EQUITY COMMITTEE OF THE SCHOOL OF HUMANITIES, ARTS, & SOCIAL SCIENCES, MIT - CORDINATING INSTUCTOR OF THIS COURSE

Prof. edward schiapa.

Prof. Edward Schiappa is the former head of comparative media studies/writing and is MIT’s John E. Burchard Professor of the Humanities. He conducts research in argumentation, persuasion, media influence, and contemporary rhetorical theory. He has published 10 books, and his research has appeared in Philosophy & Rhetoric, Argumentation, Communication Monographs, and Communication Theory.

PROFESSOR IN THE DEPARTMENT OF ELECTRICAL ENGINEERING AND COMPUTER SCIENCE AT MIT

Prof. devavrat shah.

Devavrat Shah is an Andrew (1956) and Erna Viterbi Professor of the Department of Electrical Engineering and Computer Science at MIT and the faculty director of the MicroMasters in Statistics and Data Science program with the MIT Institute for Data, Systems, and Society. He also is a member of the Laboratory for Information and Decision Systems (LIDS) and the Operations Research Center (ORC) at MIT. He currently directs the Deshpande Center for Technological Innovation at MIT.

His current research interest is in developing large-scale machine learning algorithms for unstructured data, with particular interest in social data. He has made contributions to the development of “gossip” protocols and “message-passing” algorithms for statistical inference that have been pillars of modern distributed data processing systems.

He cofounded Celect, Inc., which has been part of Nike since 2019. In 2019, he cofounded Ikigai Labs with the mission of building self-driving organizations by empowering data business operators to make data-driven decisions with the ease of spreadsheets.

PROFESSOR, INSTITUTE FOR DATA, SYSTEMS, AND SOCIETY, MIT

Prof. jessika trancik.

Jessika Trancik is a professor in the Institute for Data, Systems, and Society at the Massachusetts Institute of Technology. Her research examines the impacts of technologies and the reasons behind technological change. She has developed theory and predictive models to understand why some technologies improve faster than others, and what technology features enable rapid innovation. Trancik has developed models for forecasting technological change, which inform engineering design, public policy, and investment portfolios. Several of her theories and models have been applied to new and developing energy technologies, such as solar energy and batteries, and to electricity and transportation systems. Her models have also been used to inform government innovation policy, and applied in diverse industries, including finance, healthcare, manufacturing, software, and consumer products. Her work has been published in journals such as Nature, Proceedings of the National Academy of Sciences, Nature Energy, Nature Climate Change, and Environmental Science and Technology, and has been featured by news outlets such as the New York Times, Washington Post, Financial Times, and NPR.

Three blurbs:

- Professor Trancik received her B.S. from Cornell University and her Ph.D. from the University of Oxford as a Rhodes Scholar.

- She has developed theory and predictive models to understand why some technologies improve faster than others, and what technology features enable rapid innovation.

- Her models have also been used to inform government innovation policy, and applied in diverse industries, including finance, healthcare, manufacturing, software, and consumer products.

Discover the experience of our participants

VIKTOR LUNDBERG

CEO & Founder at Rocket AB

Great course that gave me a great overview of the business value of agile organisations using new technologies.

- Professional Certificate Program in Industry 4.0

SANJAY K. SHARMA

Chief Technology Officer, SWP at SEI

This is an excellent and very balanced course with lots of reference information, hands on exercises and case studies. Overall, a great learning opportunity, excellent faculty and excellent facilitator with lots of real-life case studies to learn”.

RENZO BARRENECHEA

Senior Product Manager at Telefonica

Many of the discoveries contributed a lot to my personal development, but at the moment of integrating them I had a wow moment that allowed me to see further in my strategy and my position as a leader.

Application Process

Complete the application form and pay the non-refundable fee.

Receive a call for an interview with our admissions team

Our Admission Committee will inform the final decision*. *(2 business days max)

Are you ready to drive growth and efficiency within your organization?

ONLINE TRAINING

Professional Certificates Online Courses Corporate Programs

DIGITAL EXPERIENCE

The Experience MIT Professional Education Fire Hydrant Award Online Professional Certificate Programs

Blog Events

CONTACT DPP

MIT Professional Education Our Faculty Our Professional Alumni FAQs

Privacy policy Terms of Service

ACCESSIBILITY

© MIT Professional Education 2024

- Blended Professional Certificate Program: Chief Digital Officer

- Blended Professional Certificate Program: Chief Product Officer

- Blended Professional Certificate Program: Chief Sustainability Officer

- Blended Professional Certificate Program: Chief Technology Officer

- Professional Certificate Program in Digital Transformation

- Professional Certificate Program in Product Management

- Professional Certificate Program in Strategic Technology Roadmapping and Innovation

- Professional Certificate Program in Sustainability

- Blockchain: Disruptive Technology

- Circular Economy: Transition for Future Sustainability

- Clean Energy Solutions: Technological Change to Meet Emissions Reduction Targets

- Cloud & DevOps: Continuous Transformation

- Competitive Strategy: Aligning Sustainability and Strategic Transformation

- Cultural Awareness for Global Business

- Data Leadership

- Designing High Impact Solutions with MITdesignX

- Designing Product Families: From Strategy to Implementation

- Digital Transformation: From AI and IoT to Cloud, Blockchain, and Cybersecurity

- Forecasting Technology Innovation: Using Data for a Strategic Advantage

- Industrial Internet of Things: From Theory to Applications

- Innovation and Technology

- Leadership & Innovation

- Life Cycle Assessment: Quantifying Environmental Impacts

- Management of Technology: Roadmapping & Development

- Management of Technology: Strategy & Portfolio Analysis

- New Space Economy: Technologies, Products, Services, and Business Models

- Persuasive Communication: Critical Thinking to Enhance your Message

- Smart Manufacturing: Moving From Static to Dynamic Manufacturing Operations

- Sustainable Infrastructure Systems: Planning and Operations

- Sustainability: Strategies and Opportunities For Industry

- Transformational Leadership: Five Practices of High Impact Innovators

- Applied Generative AI for Digital Transformation

- Bundle Program Management of Technology

- Corporate Programs

- Leading Digital Transformation

- The experience

- MIT Professional Education Fire Hydrant Award

- Online Professional Certificate Programs

- MIT Professional Education

- Our Faculty

- Our Professional Alumni

- Contact DPP

IMAGES

VIDEO

COMMENTS

Industry 4.0 is an advance development in the field industry with the revolution in automation. The industry 4.0 mainly focuses of all the manufacturing machineries with wireless technologies. Also this enables the use of advance techniques in machine learning, artificial intelligence, deep learning, reinforcement learning, game theory and so on.

Abstract. We are in the age of Industry 4.0. Evolution and advancements in information and communication technology, sensors, Big Data, the Internet of Things, 3D printing, cloud computing, robots and mobile internet are some of the key technology areas that will digitize the value chains in various industries.

Introduction. Since the term Industry 4.0 was coined in 2011 (Liao et al., 2017), a growing number of studies from different streams of research has been published on this concept (Culot et al., 2020).The literature has devoted special attention to the digital transformation of industries and companies towards an "Industry 4.0" level (Dalenogare et al., 2018).

Industry 4.0 and Advanced Production Systems. This sub-research area focuses on advanced production systems, digitalization, and automation of manufacturing processes, with specific reference to the enabling technologies of Industry 4.0 (and subsequent paradigms).

Conducting a bibliometric review, the paper identifies the key topics related to Industry 4.0 by the literature available. Published in: Article #: Date of Conference: 07-09 March 2018. Date Added to IEEE Xplore: 09 April 2018. ISBN Information: Electronic ISBN: 978-1-5386-1329-. USB ISBN: 978-1-5386-1328-3.

Capturing the full value of these rapid Industry 4.0 developments can only be realised by holistically orchestrating the implementation across a firm and its value network. To achieve this, it is vital for leadership teams to consider the inter-dependencies between individual activities and projects in key areas of their business, that may be ...

In comparison, Trotta and Garengo [4], who studied the main research topics of Industry 4.0, found that the most used keywords were: Industry 4.0, Manufacture, Internet of Things, Cyber-Physical ...

Industry 4.0 (I4.0) is a fast-evolving area of research, bringing together knowledge from multiple academic fields into creative solutions for manufacturing innovation. Despite the growing amount of published work covering a wide range of I4.0 areas, there has been relatively little research devoted to the organisational side of implementing I4.0.

Table 15. Outer Loadings of the items of Industry 4.0 ..... 85 Table 16. Construct Reliability and Validity of the items of Industry 4.0 ..... 86 Table 17. Discriminant Validity Test (Fornell Larcker Criterion) of the elements of Industry 4.0

Calibrating the PhD for Industry 4.0: global concerns, national agendas and Australian institutional responses. Tebeje Molla School of ... the Career Development Framework provides you with a holistic approach to research training covering topics such as research integrity, networking, communication skills and inter-cultural communication ...

This chapter aims to analyze the Industry 4.0 framework, identify the definition and drivers of the Industry 4.0 paradigm, discuss its potential effect, and determine obstacles of the Industry 4.0. For the research methodology, a critical literature review is performed, we relied on the recent studies related to industry 4.0. Findings - This study concluded that Industry 4.0 describes a ...

This studentship will focus on advancing the understanding of how digitalisation transforms industry and future supply chain, investigating the transformation of future supply chain into intelligent future systems by exploring the role of Industry 4.0 and Internet of Things (IoT).

Tommaso Rossi, PhD, is Full Professor of 'Smart Factory' at the Industrial Engineering School of LIUC - Cattaneo University, where he holds the courses of 'Operations Management' and 'Data Science for Management'.His main research interests are related to: network design and optimization, lean manufacturing, finite capacity materials management policies, industry 4.0 and ...

Reviews 2. Case Studies Industry 4.0 is likely to play an important role in the future society. This book is a good reference on Industry 4.0 and includes some case studies. Each chapter is written by expert researchers in the sector, and the topics are broad; from the concept or definition of Industry 4.0 to a future society 5.0.

Research opportunities. We are interested to receive applications from ambitious individuals keen to pursue research interests in Industry 4.0 at The University of Manchester. Potential PhD projects include, but are not confined to, the following: Tool wear monitoring by feed drive currents. Alternatively follow the link below to use FindaPhD ...

Industry 4.0: An Overview of Key Benefits, Technologies, and Challenges. May 2017. DOI: 10.1007/978-3-319-50660-9_1. In book: Cybersecurity for Industry 4.0: Analysis for Design and Manufacturing ...

Industry 4.0 is changing how we manage operations to drive systems more intelligently. Technologies and applications are rapidly evolving. Disruptive technologies, such as artificial intelligence, big data, cloud computing and digital twin, are shaking up different industries and have motivated us to revisit engineering and management tools for ...

Seeing that we are in 4IR era, I am trying to come up with a PHD topic "Implementation of Industry 4.0 in Higher Education(HE)" to prepare HE for this era. However, insufficient publication in the ...

Industry 4.0 in Aircraft Manufacturing: Innovative Use Cases and Patent Landscape. Vineet Bhatia, Ajay Kumar, Sumati Sidharth, Sanjeev Kumar Khare, Surendra Chandrakant Ghorpade, Parveen Kumar et al. ... workshops, and seminars for researchers, PhD, UG and PG level students. He is associated with many research, academic, and professional ...

The demands of Industry 4.0 (the Fourth Industrial Revolution) for a future-ready skilled workforce have placed significant political pressure on PhD programs to deliver different sorts of graduates.

Industry 4.0 contribution to SCR first involves delivering data-centric functions such as supply chain automation, information and communication quality, process monitoring, and visibility. Industry 4.0 further allows supply chain partners to collaborate better on improving supply chain mapping, complexity management, and innovation capabilities.

Momentum for Industry 4.0 is growing — one report by Statista projects the market will swell from $263 billion in 2021 to $1.1 trillion by 2028. Interest is surging, in part, because sensor networks are the backbone for creating feedback loops to identify hidden factories, the poorly understood processes and workarounds that drive up ...

All the participants who successfully complete Industry 4.0 will recieve a Certificate of Completion from MIT Professional Education. Furthermore, the participants who complete the program recieve 36.6 Continuing Education Units (CEUs)*. To obtain CEUs, complete the accreditation confirmation, which is available at the end of the course.

In this context, Industry 4.0 is expanded to include the Healthcare sector as well, leading to the emergence of Healthcare 4.0.This concept is not limited only to manufacturing or automation but is applied in a wider scope which aims to improve the overall level of processes in manufacturing units, healthcare services provided, as well as operational matters of healthcare systems.