Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

The sustainability of industrial hemp: a literature review of its economic, environmental, and social sustainability.

1. Introduction

2. methodology, 3.1. industrial hemp plant, 3.2. parts and uses for the industrial hemp plant, 3.3. sustainability of industrial hemp, 3.3.1. hemp economic sustainability.

- A wide range of products can be made with hemp.

- Hemp products account for a small percentage of food, textiles, personal care products, pharmaceuticals, and nutraceuticals sales in the U.S. and worldwide, but sales are growing quickly.

- Despite the falling production of hemp worldwide, due to its association with marijuana since the 1950s, business and policy changes, infrastructure investment, and improved production methods have led to a rebound in hemp production over the past decade.

3.3.2. Hemp Environmental Sustainability

- The criteria were set based on the author’s familiarity with the topic.

- There is a limitation to the author’s knowledge of a wide range of crops and criteria.

- There may be some criteria that deserve to be heavily weighted, depending on location (e.g., irrigation may be more critical in areas with low water availability).

3.3.3. Hemp Social Sustainability

4. conclusions, author contributions, conflicts of interest.

- Letcher, T.M. Global warming—A complex situation. In Climate Change ; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–17. [ Google Scholar ]

- Al-Delaimy, W.; Ramanathan, V.; Sánchez Sorondo, M. Health of People, Health of Planet and Our Responsibility: Climate Change, Air Pollution and Health ; Springer Nature: Berlin/Heidelberg, Germany, 2020. [ Google Scholar ] [ CrossRef ]

- Singh, R.L.; Singh, P.K. Global environmental problems. In Principles and Applications of Environmental Biotechnology for a Sustainable Future ; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–41. [ Google Scholar ] [ CrossRef ]

- McMichael, A.J.; Lindgren, E. Climate change: Present and future risks to health, and necessary responses. J. Intern. Med. 2011 , 270 , 401–413. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Agrawal, D.C.; Kumar, R.; Dhanasekaran, M. Cannabis/Hemp for Sustainable Agriculture and Materials ; Springer: Berlin/Heidelberg, Germany, 2022. [ Google Scholar ] [ CrossRef ]

- Pal, L.; Lucia, L.A. Renaissance of industrial hemp: A miracle crop for a multitude of products. BioResources 2019 , 14 , 2460–2464. [ Google Scholar ]

- Thedinger, S. Prohibition in the United States: International and US regulation and control of industrial hemp. Colo. J. Int’l Envtl. L. Pol’y 2005 , 17 , 419. [ Google Scholar ]

- Musto, D.F. The marihuana tax act of 1937. Arch. Gen. Psychiatry 1972 , 26 , 101–108. [ Google Scholar ] [ CrossRef ]

- Johnson, R. Defining hemp: A fact sheet. Congr. Res. Serv. 2019 , 44742. [ Google Scholar ]

- NCSL. State Industrial Hemp Statutes. 2020. Available online: https://www.ncsl.org/agriculture-and-rural-development/state-industrial-hemp-statutes (accessed on 8 June 2022).

- Fortenbery, T.R.; Bennett, M. Is Industrial Hemp Worth Further Study in the US? A Survey of the Literature. 2001. Available online: https://doi.org/10.22004/ag.econ.12680 (accessed on 8 June 2022).

- Jeliazkov, V.D.; Noller, J.S.; Angima, S.; Rondon, S.I.; Roseberg, R.J.; Summers, S.; Jones, G.B.; Sikora, V. What is Industrial Hemp? Oregon State University Extension Service: Corvallis, OR, USA, 2019. [ Google Scholar ]

- Miller, N.G. The genera of the Cannabaceae in the southeastern United States. J. Arnold Arbor. 1970 , 51 , 185–203. [ Google Scholar ] [ CrossRef ]

- Agate, S.; Tyagi, P.; Naithani, V.; Lucia, L.; Pal, L. Innovating generation of nanocellulose from industrial hemp by dual asymmetric centrifugation. ACS Sustain. Chem. Eng. 2020 , 8 , 1850–1858. [ Google Scholar ] [ CrossRef ]

- Atakan, Z. Cannabis, a complex plant: Different compounds and different effects on individuals. Ther. Adv. Psychopharmacol. 2012 , 2 , 241–254. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Simiyu, D.C.; Jang, J.H.; Lee, O.R. Understanding Cannabis sativa L.: Current Status of Propagation, Use, Legalization, and Haploid-Inducer-Mediated Genetic Engineering. Plants 2022 , 11 , 1236. [ Google Scholar ] [ CrossRef ]

- Iseger, T.A.; Bossong, M.G. A systematic review of the antipsychotic properties of cannabidiol in humans. Schizophr. Res. 2015 , 162 , 153–161. [ Google Scholar ] [ CrossRef ]

- Bridgeman, M.B.; Abazia, D.T. Medicinal cannabis: History, pharmacology, and implications for the acute care setting. Pharm. Ther. 2017 , 42 , 180. [ Google Scholar ]

- Rupasinghe, H.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp ( Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020 , 25 , 4078. [ Google Scholar ] [ CrossRef ]

- USDA. Industrial Hemp in the United States: Status and Market Potential ; USDA: Washingtion, DC, USA, 2000; p. 182773. Available online: https://www.ers.usda.gov/webdocs/publications/41740/15867_ages001e_1_.pdf?v=42087 (accessed on 8 June 2022).

- Sgrò, S.; Lavezzi, B.; Caprari, C.; Polito, M.; D’Elia, M.; Lago, G.; Furlan, G.; Girotti, S.; Ferri, E.N. Delta9-THC determination by the EU official method: Evaluation of measurement uncertainty and compliance assessment of hemp samples. Anal. Bioanal. Chem. 2021 , 413 , 3399–3410. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Zhao, H.; Xiong, H.; Chen, J. Regional Comparison and Strategy Recommendations of Industrial Hemp in China Based on a SWOT Analysis. Sustainability 2021 , 13 , 6419. [ Google Scholar ] [ CrossRef ]

- Arnall, B.; Bushong, J.; Lofton, J. Agronomic Considerations for Industrial Hemp Production ; Oklahoma Cooperative Extension Service: Stillwater, OK, USA, 2019. [ Google Scholar ]

- Marsh, G. Next step for automotive materials. Mater. Today 2003 , 4 , 36–43. [ Google Scholar ] [ CrossRef ]

- Ouajai, S.; Shanks, R. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005 , 89 , 327–335. [ Google Scholar ] [ CrossRef ]

- John, F.; Williams, D.; Trey, R.; Jared, N.; Patrick, F.; Jeff, K.; Williams, D.; Williams, R.; Brian, C.; Dong, Z. Industrial Hemp as a Modern Commodity Crop ; American Society of Agronomy: Madison, WI, USA, 2019. [ Google Scholar ] [ CrossRef ]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014 , 7 , 8131–8150. [ Google Scholar ] [ CrossRef ]

- Li, X.; Wu, N.; Morrell, J.J.; Du, G.; Tang, Z.; Wu, Z.; Zou, C. Influence of hemp plant eccentric growth on physical properties and chemical compounds of hemp hurd. BioResources 2018 , 13 , 290–298. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Johnson, R. Hemp as an Agricultural Commodity ; Library of Congress Washington DC Congressional Research Service: Washington, DC, USA, 2014. [ Google Scholar ]

- Johnson, R. Production, Marketing, and Regulation of Hemp Products ; IF11860; Congressional Research Service: Washington, DC, USA, 2021. Available online: https://crsreports.congress.gov/product/pdf/IF/IF11860 (accessed on 8 June 2022).

- Deitch, R. Hemp: American History Revisited: The Plant with a Divided History ; Algora Publishing: New York, NY, USA, 2003. [ Google Scholar ]

- Kraenzel, D.G. Industrial Hemp as an Alternative Crop in North Dakota: A White Paper Study of the Markets, Profitability, Processing, Agronomics and History ; North Dakota State University: Fargo, ND, USA, 1998. [ Google Scholar ] [ CrossRef ]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp ( Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020 , 12 , 1935. [ Google Scholar ] [ CrossRef ]

- FAOSTAT FAO. Available online: https://www.fao.org/faostat/en/#home (accessed on 14 August 2022).

- Zimniewska, M. Hemp fibre properties and processing target textile: A review. Materials 2022 , 15 , 1901. [ Google Scholar ] [ CrossRef ]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007 , 103 , 2432–2441. [ Google Scholar ] [ CrossRef ]

- Small, E.; Pocock, T.; Cavers, P. The biology of Canadian weeds. 119. Cannabis sativa L. Can. J. Plant Sci. 2003 , 83 , 217–237. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Sen, T.; Reddy, H.J. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011 , 2 , 192. [ Google Scholar ]

- Fan, M. Characterization and Performance of Elementary Hemp Fibres: Factors Influencing Tensile Strength. Bioresources 2010 , 5 , 2307–2322. [ Google Scholar ] [ CrossRef ]

- Anderson, J.; Jansz, A.; Steele, K.; Thistlethwaite, P.; Bishop, G.; Black, A. Green Guide to Composites: An Environmental Profiling System for Composite Materials and Products ; BRE Press: Berkshire, UK, 2004. [ Google Scholar ]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009 , 91 , 1–21. [ Google Scholar ] [ CrossRef ]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life cycle impact assessment. In Life Cycle Assessment: Theory and Practice ; Springer: Cham, Switzerland, 2018; pp. 167–270. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Curran, M. Encyclopedia of ecology. Encycl. Ecol. 2008 , 2168–2174. [ Google Scholar ] [ CrossRef ]

- Duda, M.; Shaw, J.S. Life cycle assessment. Society 1997 , 35 , 38–43. [ Google Scholar ] [ CrossRef ]

- GrandViewResearch. Eco Fiber Market Size, Share & Trends Analysis Report By Product (Organic, Manmade/Regenerated, Recycled) By Application (Textiles/Apparel, Industrial, Medical), By Region, And Segment Forecasts, 2023–2030. 2020. Available online: https://www.grandviewresearch.com/industry-analysis/eco-fiber-market (accessed on 8 June 2022).

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004 , 140 , 65–72. [ Google Scholar ] [ CrossRef ]

- Crescente, G.; Piccolella, S.; Esposito, A.; Scognamiglio, M.; Fiorentino, A.; Pacifico, S. Chemical composition and nutraceutical properties of hempseed: An ancient food with actual functional value. Phytochem. Rev. 2018 , 17 , 733–749. [ Google Scholar ] [ CrossRef ]

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial hemp seed: From the field to value-added food ingredients. J. Cannabis Res. 2022 , 4 , 1–13. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Mead, A. The legal status of cannabis (marijuana) and cannabidiol (CBD) under US law. Epilepsy Behav. 2017 , 70 , 288–291. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Barbier, E.B. The concept of sustainable economic development. Environ. Conserv. 1987 , 14 , 101–110. [ Google Scholar ] [ CrossRef ]

- Duran, D.C.; Gogan, L.M.; Artene, A.; Duran, V. The components of sustainable development-a possible approach. Procedia Econ. Financ. 2015 , 26 , 806–811. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Giddings, B.; Hopwood, B.; O’brien, G. Environment, economy and society: Fitting them together into sustainable development. Sustain. Dev. 2002 , 10 , 187–196. [ Google Scholar ] [ CrossRef ]

- Goodland, R. Sustainability: Human, social, economic and environmental. Encycl. Glob. Environ. Change 2002 , 5 , 481–491. [ Google Scholar ]

- Small, E.; Marcus, D. Hemp: A new crop with new uses for North America. Trends New Crops New Uses 2002 , 24 , 284–326. [ Google Scholar ]

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic viability of industrial hemp in the United States: A review of state pilot programs. AgEcon Search Res. Agricul. Appl. Econ. 2020 . [ Google Scholar ] [ CrossRef ]

- Mark, T.B.; Will, S. Economic issues and perspectives for industrial hemp. In Industrial Hemp as a Modern Commodity Crop ; American Society of Agronomy: Madison, WI, USA, 2019; pp. 107–118. [ Google Scholar ] [ CrossRef ]

- USDA. Remediation and Disposal Guidelines for Hemp Growing Facilities, U.S. Domestic Hemp Production Program ; 2021. Available online: https://www.ams.usda.gov/sites/default/files/media/HempRemediationandDisposalGuidelines.pdf (accessed on 8 June 2022).

- Australia, A. Industrial Hemp. 2017. Available online: https://www.agrifutures.com.au/farm-diversity/industrial-hemp/ (accessed on 18 November 2022).

- Panchenko, V.; Izmailov, A.; Kharchenko, V.; Lobachevskiy, Y. Photovoltaic solar modules of different types and designs for energy supply. In Research Anthology on Clean Energy Management and Solutions ; IGI Global: Hershey, PA, USA, 2021; pp. 731–752. [ Google Scholar ]

- ExpertMarketResearch. Global Industrial Hemp Market: By Source: Conventional, Organic; By Product Type: Hemp Seed, Hemp Fibre, Hemp Seed Oil, CBD hemp Oil; By Application: Food and Beverages, Personal Care, Pharmaceuticals; Regional Analysis; Historical Market and Forecast. Available online: https://www.expertmarketresearch.com/reports/industrial-hemp-market (accessed on 8 June 2022).

- MarketsandMarkets. Industrial Hemp Market by Type (Hemp Seed, Hemp Seed Oil, Hemp Fiber, and CBD Hemp Oil), Application (Food, Beverages, Personal Care Products, Textiles, and Pharmaceuticals), Source (Organic and Conventional), and Region—Global Forecast to 2025. 2019. Available online: https://www.marketsandmarkets.com/Market-Reports/industrial-hemp-market-84188417.html (accessed on 8 June 2022).

- MarketDataForecast. Global Industrial Hemp Market Size, Share, Trends, COVID-19 Impact & Growth Analysis Report—Segmented By Type, Application and Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa)—Industry Forecast (2022 to 2027). 2022. Available online: https://www.marketdataforecast.com/market-reports/industrial-hemp-market (accessed on 8 June 2022).

- Imarc. Industrial Hemp Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027; SR112023A4473. 2022. Available online: https://www.imarcgroup.com/industrial-hemp-market (accessed on 8 June 2022).

- Schmidt, E. Hemp & CBD market value: January 2020 price trends for crude, flower biomass isolate. ACS Lab. 2020 . [ Google Scholar ]

- Allen, C.; Whitney, B. The Field of Dreams. An Economic Survey of the United States Hemp Cultivation Industry ; Whitney Economics: Portland, Oregon, 2019. [ Google Scholar ]

- Euromonitor International. Alcoholic & Soft Drinks and Packaged Food—Market Size Data. 2020. Available online: https://www.euromonitor.com/industries (accessed on 10 October 2022).

- Technavio. Global Textile Market 2019–2023. 2019. Available online: https://www.technavio.com/report/textile-manufacturing-market-analysis (accessed on 10 October 2022).

- Euromonitor International. Beauty and Personal Care—Market Size Data. 2020. Available online: https://www.euromonitor.com/beauty-and-personal-care (accessed on 10 October 2022).

- Wagner, C. What is Industrial Hemp? Open Hemp University: Oakland, CA, USA, 2015. [ Google Scholar ] [ CrossRef ]

- Victoria State Government. 2020 Industrial Hemp Update-Industrial Hemp Taskforce ; State of Victoria, Department of Jobs, Precincts and Regions: Melbourne, Australia, 2020. [ Google Scholar ]

- Cherney, J.H.; Small, E. Industrial hemp in North America: Production, politics and potential. Agronomy 2016 , 6 , 58. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- McGrath, C. Hemp Annual Report ; Report No. CH2020-0018; USDAFAS: Washington, DC, USA, 2019. [ Google Scholar ]

- Horner, J.; Milhollin, R.; Roach, A.; Morrison, C.; Schneider, R. Comparative Analysis of the Industrial Hemp Industry: Guide to the Evolution of the US Industrial Hemp Industry in the Global Economy ; University of Missouri Extension Service: Columbia, MI, USA, 2019. [ Google Scholar ]

- Hemp. European Commission. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 3 April 2022).

- Omnes, M.-A. Industrial Hemp in France ; USDA Foreign Agricultural Service: Washington, DC, USA, 2021. [ Google Scholar ]

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, processing and applications for fibres, shivs, seeds and flowers. Eur. Ind. Hemp Assoc. 2016 , 5 , 1–9. [ Google Scholar ]

- USDA. National Hemp Report ; USDA National Agricultural Statistics Service: Washington, DC, USA, 2022. [ Google Scholar ]

- Dhondt, F.; Muthu, S.S.; Dhondt, F.; Muthu, S.S. The Environmental and Social Impacts of Hemp. In Hemp and Sustainability ; Springer: Singapore, 2021; pp. 15–35. [ Google Scholar ] [ CrossRef ]

- Bouloc, P.; Allegret, S.; Arnaud, L. Hemp: Industrial Production and Uses ; CABI: Wallingford, UK, 2013. [ Google Scholar ]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004 , 140 , 1–6. [ Google Scholar ] [ CrossRef ]

- Valić, F.; Žuškin, E. Effects of different vegetable dust exposures. Occup. Environ. Med. 1972 , 29 , 293–297. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Roulac, J.W. Hemp Horizons: The Comeback of the World’s Most Promising Plant ; Chelsea Green Publishing Company: Chelsea, VT, USA, 1997. [ Google Scholar ]

- Schultes, R.E. Random Thoughts and Queries on the Botany of Cannabis ; J. & A. Churchill: London, UK, 1970. [ Google Scholar ]

- Montford, S.; Small, E. A comparison of the biodiversity friendliness of crops with special reference to hemp ( Cannabis sativa L.). J. Int. Hemp Assoc 1999 , 6 , 53–63. [ Google Scholar ]

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The social dimension of sustainable development: Defining urban social sustainability. Sustain. Dev. 2011 , 19 , 289–300. [ Google Scholar ] [ CrossRef ]

- Donham, K.J.; Thelin, A. Agricultural Medicine: Rural Occupational and Environmental Health, Safety, and Prevention ; John Wiley & Sons: Hoboken, NJ, USA, 2016. [ Google Scholar ]

- Bouhuys, A.; Barbero, A.; Lindell, S.-E.; Roach, S.; Schilling, R. Byssinosis in hemp workers. Arch. Environ. Health Int. J. 1967 , 14 , 533–543. [ Google Scholar ] [ CrossRef ]

- Zuskin, E.; Kanceljak, B.; Pokrajac, D.; Schachter, E.; Witek, T. Respiratory symptoms and lung function in hemp workers. Occup. Environ. Med. 1990 , 47 , 627–632. [ Google Scholar ] [ CrossRef ] [ PubMed ] [ Green Version ]

- McPartland, J.M. Byssinosis in hemp mill workers. J. Ind. Hemp 2003 , 8 , 33–44. [ Google Scholar ] [ CrossRef ]

- Valić, F.; Žuškin, E.; Walford, J.; Keršić, W.; Pauković, R. Byssinosis, chronic bronchitis, and ventilatory capacities in workers exposed to soft hemp dust. Occup. Environ. Med. 1968 , 25 , 176–186. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Fishwick, D.; Pickering, C. Byssinosis--a form of occupational asthma? Thorax 1992 , 47 , 401. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Blair, A.; Ritz, B.; Wesseling, C.; Freeman, L.B. Pesticides and Human Health ; BMJ Publishing Group Ltd.: London, UK, 2015; Volume 72, pp. 81–82. [ Google Scholar ] [ CrossRef ]

- Sankhla, M.S.; Kumari, M.; Sharma, K.; Kushwah, R.S.; Kumar, R. Water contamination through pesticide & their toxic effect on human health. Int. J. Res. Appl. Sci. Eng. Technol. 2018 , 6 , 967–970. [ Google Scholar ] [ CrossRef ]

- Alavanja, M.C.; Bonner, M.R. Occupational pesticide exposures and cancer risk: A review. J. Toxicol. Environ. Health Part B 2012 , 15 , 238–263. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Davidson, M.; Reed, S.; Oosthuizen, J.; O’Donnell, G.; Gaur, P.; Cross, M.; Dennis, G. Occupational health and safety in cannabis production: An Australian perspective. Int. J. Occup. Environ. Health 2018 , 24 , 75–85. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Martyny, J.W.; Serrano, K.A.; Schaeffer, J.W.; Van Dyke, M.V. Potential exposures associated with indoor marijuana growing operations. J. Occup. Environ. Hyg. 2013 , 10 , 622–639. [ Google Scholar ] [ CrossRef ]

- KG, S.; Das, S. Hazards Associated with Dying in Finishing Process of a Textile Industry. Int. Res. J. Eng. Technol. 2019 , 6. [ Google Scholar ]

- Malik, N.; Maan, A.A.; Pasha, T.S.; Akhtar, S.; Ali, T. Role of hazard control measures in occupational health and safety in the textile industry of Pakistan. Pak. J. Agri. Sci. 2010 , 47 , 72–76. [ Google Scholar ]

- Freeman, G.L. Allergic skin test reactivity to marijuana in the Southwest. West. J. Med. 1983 , 138 , 829. [ Google Scholar ] [ PubMed ]

- Kumar, R.; Gupta, N. A case of bronchial asthma and allergic rhinitis exacerbated during Cannabis pollination and subsequently controlled by subcutaneous immunotherapy. Indian J. Allergy Asthma Immunol. 2013 , 27 , 143. [ Google Scholar ] [ CrossRef ]

- Stokes, J.R.; Hartel, R.; Ford, L.B.; Casale, T.B. Cannabis (hemp) positive skin tests and respiratory symptoms. Ann. Allergy Asthma Immunol. 2000 , 85 , 238–240. [ Google Scholar ] [ CrossRef ]

- Williams, C.; Thompstone, J.; Wilkinson, M. Work-related contact urticaria to Cannabis sativa . Contact Dermat. 2008 , 58 , 62–63. [ Google Scholar ] [ CrossRef ]

- Fishwick, D.; Allan, L.; Wright, A.; Barber, C.; Curran, A. Respiratory symptoms, lung function and cell surface markers in a group of hemp fiber processors. Am. J. Ind. Med. 2001 , 39 , 419–425. [ Google Scholar ] [ CrossRef ]

- Wang, S.; Gusovius, H.-J.; Lühr, C.; Musio, S.; Uhrlaub, B.; Amaducci, S.; Müssig, J. Assessment system to characterise and compare different hemp varieties based on a developed lab-scaled decortication system. Ind. Crops Prod. 2018 , 117 , 159–168. [ Google Scholar ] [ CrossRef ]

- Turunen, L.; Van der Werf, H. Life cycle analysis of hemp textile yarn, comparison of three hemp fiber processing scenarios and a flax scenario. J. Ind. Hemp 2006 , 12 , 43–66. [ Google Scholar ] [ CrossRef ]

- Grace Annapoorani, S. Social sustainability in textile industry. In Sustainability in the Textile Industry ; Springer: Singapore, 2017; pp. 57–78. [ Google Scholar ] [ CrossRef ]

- Sakthi Nagaraj, T.; Jeyapaul, R.; Vimal, K.; Mathiyazhagan, K. Integration of human factors and ergonomics into lean implementation: Ergonomic-value stream map approach in the textile industry. Prod. Plan. Control. 2019 , 30 , 1265–1282. [ Google Scholar ] [ CrossRef ]

- Polat, O.; Kalayci, C.B. Ergonomic risk assessment of workers in garment industry. In Proceedings of the Eight International Conference on Textile Science & Economy VIII, Zranjanin, Sarbia, 16–19 May 2016; pp. 16–21. [ Google Scholar ]

- Hamm, B. Challenges to secure human rights through voluntary standards in the textile and clothing industry. In Business and Human Rights ; Edward Elgar Publishing: Northampton, MA, USA, 2012; pp. 220–242. [ Google Scholar ]

- Organization, I.L. Promoting fair globalization in textiles and clothing in a post-MFA environment: Report for Discussion at the Tripartite Meeting on Promoting Fair Globaliztion in Textiles and Clothing in a Post-MFA Environment ; International Labour Office: Geneva, Switzerland, 2005. [ Google Scholar ]

- Committee, I.C.A. Literature Review and Research Evaluation Relating to Social Impacts of Global Cotton Production for ICAC Expert Panel on Social, Environmental and Economic Performance of Cotton (SEEP) ; Prepared by Ergon; International Cotton Advisory Committee: Washington, DC, USA, 2008. [ Google Scholar ]

- Wills, J.; Hale, A. Threads of labour in the global garment industry. In Threads of Labour: Garment Industry Supply Chains from the Workers’ Perspective ; Wiley-Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2005; pp. 1–15. [ Google Scholar ] [ CrossRef ]

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.i. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021 , 26 , 215–220. [ Google Scholar ] [ CrossRef ]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A. Planetary boundaries: Guiding human development on a changing planet. Science 2015 , 347 , 1259855. [ Google Scholar ] [ CrossRef ] [ Green Version ]

Click here to enlarge figure

| The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Share and Cite

Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023 , 15 , 6457. https://doi.org/10.3390/su15086457

Kaur G, Kander R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability . 2023; 15(8):6457. https://doi.org/10.3390/su15086457

Kaur, Gurinder, and Ronald Kander. 2023. "The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability" Sustainability 15, no. 8: 6457. https://doi.org/10.3390/su15086457

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

- Search term Advanced Search Citation Search

- Individual login

- Institutional login

Consumer response to hemp: A case study of Vermont residents from 2019 to 2020

Corresponding Author

Jane Kolodinsky

- [email protected]

- orcid.org/0000-0001-7322-0889

Community Development and Applied Economics, University of Vermont, Burlington, VT, USA

Correspondence

Jane Kolodinsky, Community Development and Applied Economics, University of Vermont, Burlington, VT, USA.

Email: [email protected]

Hannah Lacasse

- orcid.org/0000-0002-4682-1168

Hemp has emerged as a novel crop and ingredient for sustainable products. If innovative hemp-based products are to succeed in the market, the surge of interest in production must be accompanied by information generation across the supply chain. At present, there is little knowledge on consumer behavior toward hemp and hemp-based products, and even less on how this behavior has changed since hemp's reintroduction to the production landscape of the United States in 2014. This study compares representative survey data of Vermont residents in 2019 and 2020 on their support for hemp production, and awareness and use of hemp-based products. Although the influence of demographic variables did not significantly change over time, our findings reveal structural change, with more respondents aware of and using hemp-based products in 2020 compared to 2019. These findings point to hemp's growing presence and acceptance in the marketplace, where consumers are more informed about or have greater access to hemp products. Despite the state's focus on cannabidiol production, Vermonters appear to be aware of and are purchasing a variety of hemp goods, such as clothing and paper.

1 INTRODUCTION

Hemp ( Cannabis sativa ) has reemerged in the market landscape of the United States as a sustainable crop and product alternative. The crop's floral, grain, and fiber material can act as substitutes for synthetic fossil fuel-based ingredients, and create thousands of value-added products (Das et al., 2017 ; Langeveld et al., 2010 ; Popular Mechanics Magazine, 1938 ). Hemp can serve as a low energy crop, whose biomass can provide a myriad of bioenergy outputs (Finnan & Styles, 2013 ; Papadopoulou et al., 2015 ; Rehman et al., 2013 ). These characteristics make hemp a viable input for a bioeconomy, where renewable resources serve as the basis for value-added materials, products, and energy (Amaducci et al., 2015 ; McCormick & Kautto, 2013 ; Tang et al., 2017 ).

Hemp production was reintroduced to the United States with the passing of the 2014 Farm Bill, which allowed for state-based research and pilot programs ( Legitimacy of Industrial Hemp Research , 2014 ). The federal legalization of hemp in 2018 triggered national interest in its production and commercialization ( Agriculture Improvement Act of 2018 , 2018 ). The U.S. Department of Agriculture (USDA) reports that hemp acreage increased by nearly 350% from 2018 to 2019, with a focus on floral harvest for essential oil and cannabidiol (CBD) production (Mark et al., 2020 ). CBD has been an appealing production prospect due to rising consumer demand and high economic returns (Mark et al., 2020 ; Mark & Snell, 2019 ). However, the report also points to the uncertainty of land availability, oversupply, market transparency, risk management, and government regulation that this nascent sector must manage in the coming years. An absence of peer-reviewed research and data on the hemp consumer market nationally have been identified as an active hurdle to addressing these challenges (Ellison, 2020 ; Mark et al., 2020 ). Knowledge on CBD demand is particularly crucial due to volatile prices and rigorous regulation (Mark et al., 2020 ). For some states, such as Kentucky and Colorado, the CBD market has already experienced price volatility since hemp's legalization, with biomass prices peaking in July of 2019 at approximately $4.50 per percentage CBD per pound and dropping in January of 2020 to nearly 50 cents per percentage CBD per pound, threatening the resilience and longevity of producers (Mark, 2020 ). Thus, this study seeks to contribute to this gap in literature through an analysis of Vermont residents' behavior toward hemp and hemp-based products, including CBD products, over time.

Vermont serves as a comparable lens from which to view hemp's development in the United States. The state's percentage growth for number of registrations and registered hemp acres from 2016 to 2019 is approximate to that of the United States as a whole (Figures 1 and 2 ). Vermont also shares similar production concerns expressed by the rest of the country, including fair pricing and market saturation (McCallum, 2019 ; Wallace Allen, 2019 ). By the end of the 2019 harvesting season, 50% of surveyed hemp growers did not have a buyer for their material (Vermont Agency of Agriculture Food & Markets, 2019 ). Given these challenges, registered acres and registrations have dropped from 2019 to 2020 in Vermont (Figures 1a and 2a ).

Insight into consumer demand and behavior toward hemp-based products is critical to help direct risk management and production strategies for growers and processors (Mark et al., 2020 ). Understanding the hemp consumer will play an important role in constructing a robust and resilient industry. A 2019 survey identified market demand as the most highly anticipated research category for hemp producers (Ellison, 2020 ) and the USDA notes that market and economic research on national hemp production is absent (Mark et al., 2020 ). Although producers have been quick to adopt this innovative crop, there is scant peer-reviewed research on how consumers have responded to its resurgence. Research on internet searches in the United States reveals a rise in searches for CBD between 2014 and 2018, with search volumes increasing by 160% from 2017 to 2018 (Leas et al., 2019 ). Kolodinsky et al. ( 2020 ) find that consumer demand for hemp-based products in Vermont may extend beyond CBD products, including clothing and personal care products. However, this is the only published, peer-reviewed literature on consumer behavior toward hemp in Vermont and in the United States more broadly to date. Industry derived data on consumer demand for hemp are largely focused on CBD products, with men and older consumers more likely to consumer CBD products (New Frontier Data, 2020a ). Kim and Mark ( 2018 ) have also analyzed Nielsen Consumer Panel data to evaluate the influence of demographics on cereal, nuts, vitamins, and medications. Given hemp's historic ties to marijuana, indication of consumer acceptance of hemp and their response to all types of hemp products on the market is critical to allow for educated production and marketing decisions (Malone & Gomez, 2019 ). This study builds this knowledge base through a comparison of 2019 and 2020 survey data of Vermont consumers on their support for hemp production, and familiarity with and use of hemp-based products. Given the timing of hemp's federal legalization, Vermont's hemp harvest period, and the data collection period, this study represents a comparison of consumer behavior between the 2019 and 2020 growing seasons.

2 MATERIALS AND METHODS

2.1 materials.

This study analyzes data collected by the University of Vermont's Center for Rural Studies through a statistically representative telephone survey of Vermont residents. Approved by the Institutional Review Board at the University of Vermont, data were collected in February and March of both 2019 and 2020. Trained interviewers conducted the survey using computer-aided telephone interviewing. Respondents were chosen through random sampling from a list of Vermont landline and cell phone numbers. Respondents were randomly selected each year of data collection; thus, these data serve as cross-sectional samples where the identities of individual respondents cannot be discerned. To participate in the survey, respondents had to be current residents of Vermont and 18 years or older. Complete responses required for the logistic regressions conducted in this study ranged from 934 to 946 and results have a margin of error ranging from ±3.204% to ±3.184% with a confidence level of 95%. IBM ® SPSS ® Version 26 was used to conduct all statistical analyses.

2.2 Methods

This study characterizes consumer behavior toward hemp and hemp products through three survey questions: support for industrial hemp production, familiarity with hemp-based products, and use of hemp-based products. Support for hemp production was collected through a five-point Likert scale, ranging from strongly opposed to strongly supportive. For the purposes of this study, this variable was recoded into those who are somewhat or strongly supportive compared to all other responses. Respondents were asked whether they were familiar with hemp CBD oil, hemp clothing or shoes, and hemp paper. General familiarity is defined as whether respondents indicated they were familiar with at least one of these three product categories. Respondents were also asked whether they use hemp-based products, including hemp CBD oil and hemp clothing. General familiarity is defined as whether respondents indicated that they use at least one category of product.

Sociodemographic data were collected for both survey years (Table 1 ). Age was measured continuously. Education is categorically measured into six levels of education. This sample appears to be more highly educated than Vermont census indications; those with a bachelor's degree or higher being greater in our sample (53.4%) than state estimates (37.3%; United States Census Bureau, 2019 ). Female representation is higher in our sample (59.2%) than census estimates (50.6%; United States Census Bureau, 2019 ). Median household income for the state is $60,076 and those with an annual income of $50,000 or higher in our sample are 65.8% (United States Census Bureau, 2019 ). In order to determine urban vs. rural influence, a location variable was created to compare those residing in Chittenden County, the most populous Vermont county, with everyone else (Vermont Department of Health, 2019 ). Both our sample and census estimates indicate that 26% of Vermont residents reside in Chittenden County (United States Census Bureau, 2019 ).

| Variable | Definition | 2019 | 2020 | Cumulative | |||

|---|---|---|---|---|---|---|---|

| % | % | % | |||||

| Age | Continuous | 58.7 | 638 | 54.6 | 515 | 56.9 | 1153 |

| Education | Less than high school diploma | 3.3 | 646 | 2.5 | 525 | 2.9 | 1171 |

| High school diploma or GED | 18.7 | 17.7 | 18.3 | ||||

| Some college completed | 16.9 | 16.2 | 16.6 | ||||

| Associates or technical degree | 9.1 | 8.6 | 8.9 | ||||

| Bachelor's degree | 28.0 | 28.6 | 28.3 | ||||

| Postgraduate or greater | 24.0 | 26.5 | 25.1 | ||||

| Gender | Female | 63.2 | 650 | 54.2 | 520 | 59.2 | 1170 |

| Income | Less than $25,000/year | 12.8 | 553 | 12.9 | 457 | 12.9 | 1010 |

| $25,000–$50,000/year | 20.8 | 21.9 | 21.3 | ||||

| $50,000–$75,000/year | 22.4 | 18.4 | 20.6 | ||||

| $75,000–$100,000/year | 16.1 | 15.3 | 15.7 | ||||

| Greater than $100,000/year | 27.8 | 31.5 | 29.5 | ||||

| Political affiliation | Republican | 15.5 | 611 | 14.6 | 501 | 15.1 | 1112 |

| Democrat | 30.0 | 27.9 | 29.0 | ||||

| Independent | 29.6 | 31.9 | 30.7 | ||||

| Progressive | 7.7 | 8.0 | 7.8 | ||||

| Not politically affiliated | 17.2 | 17.6 | 17.4 | ||||

| Location | Chittenden County | 27.2 | 680 | 24.4 | 537 | 26.0 | 1217 |

- a Mean value.

The resulting LR statistic has an approximate chi-square distribution under the null hypothesis, with a critical value of 95%. If we fail to reject the null hypothesis that the restricted model was significantly different from the unrestricted model, then only the restricted model was analyzed to determine the presence of statistically significant structural change from 2019 to 2020.

The majority of respondents in both survey years are supportive of hemp production in Vermont; however, there is no statistically significant association between support and year (Table 2 ). Significantly more respondents are familiar with hemp-based products in 2020 compared with 2019 (85.3%) vs. 96.8%. The majority of respondents are familiar with hemp CBD oil and hemp clothing in both years, with significantly more being familiar in 2020. Familiarity with hemp paper has risen from 35.0% in 2019 to 61.6% in 2020. General use of hemp-based products has risen from 32.6% in 2019 to 54.7% in 2020. Use of hemp CBD and hemp clothing specifically have also risen from 2019 to 2020. All dependent variables for familiarity and use are significantly associated with year.

| Year | Supportive of hemp production | Familiarity | Use | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| General familiarity | Hemp CBD oil | Hemp clothing | Hemp paper | General use | Hemp CBD | Hemp clothing | ||||||||||

| % | % | % | % | % | % | % | % | |||||||||

| 2019 | 75.9 | 0.000 | 85.3 | 45.985 | 78.5 | 70.250 | 70.4 | 63.021 | 35.0 | 85.529 | 22.1 | 66.039 | 15.2 | 62.644 | 9.8 | 50.404 |

| 2020 | 76.0 | 96.8 | 95.3 | 89.2 | 61.6 | 44.1 | 34.8 | 25.1 | ||||||||

- Degrees of freedom for all variables are equal to 1.

- Abbreviation: CBD, cannabidiol.

- *** Significant at p < 0.001.

Likelihood ratio test results for those supportive of hemp production in Vermont lead us to fail to reject the null hypothesis that the influence of demographic variables on hemp support did not significantly change over time ( χ 2 (16) = 16.539, p = 0.420). Logistic regression results for the restricted model reveal that year is not a statistically significant predictor of hemp support ( p = 0.718; Table 3 ). Six sociodemographic variables are significantly associated with support. Age is negatively associated with hemp support, while income of $50,000–$75,000 per year, income of $75,000–$100,000 per year, Democrat affiliation, Independent affiliation, and Progressive affiliation are positively associated with hemp support.

| Variable | Definition | Exp ( ) | SE | |

|---|---|---|---|---|

| Age | Continuous | 0.989 | 0.006 | 1 |

| Education | Less than high school diploma | |||

| High school diploma or GED | 0.623 | 0.524 | 1 | |

| Some college completed | 1.024 | 0.536 | 1 | |

| Associates or technical degree | 1.156 | 0.570 | 1 | |

| Bachelor's degree | 1.182 | 0.533 | 1 | |

| Postgraduate or greater | 0.729 | 0.540 | 1 | |

| Gender | Female | 0.816 | 0.173 | 1 |

| Income | Less than $25,000/year | |||

| $25,000–$50,000/year | 1.426 | 0.273 | 1 | |

| $50,000–$75,000/year | 1.806 | 0.288 | 1 | |

| $75,000–$100,000/year | 2.443 | 0.337 | 1 | |

| Greater than $100,000/year | 1.266 | 0.282 | 1 | |

| Political affiliation | Republican | |||

| Democrat | 2.629 | 0.249 | 1 | |

| Independent | 2.821 | 0.247 | 1 | |

| Progressive | 6.277 | 0.455 | 1 | |

| Not politically affiliated | 0.946 | 0.253 | 1 | |

| Location | Chittenden County | 0.862 | 0.190 | 1 |

| Year | 2020 | 0.942 | 0.166 | 1 |

| Constant | 3.070 | 0.657 | 1 |

- a Reference category.

- * Significant at p < 0.050;

- ** Significant at p < 0.010;

Results for the LRT for general familiarity with hemp-based products lead us to fail to reject the null hypothesis that the influence of demographic variables on general familiarity with hemp did not significantly change over time ( χ 2 (16) = 25.873, p = 0.060). Logistic regression results for the restricted model reveal that year is a statistically significant predictor of general familiarity ( p = 0.001) (Table 4 ). Age and an income higher than $100,000 per year are also significant predictors of general familiarity. Older respondents are less likely to be generally familiar with hemp-based products than younger respondents by 0.943 percentage points ( p < 0.001) and those with an income higher than $100,000 per year are 3.324 times more likely to generally familiar than those with an income of less than $25,000 per year ( p = 0.001). Respondents in 2020 were 3.587 times more likely to be familiar with hemp-based products compared to 2019 ( p < 0.050).

| Variable | Definition | Exp ( ) | SE |

|---|---|---|---|

| Age | Continuous | 0.943 | 0.012 |

| Education | Less than high school diploma | ||

| High school diploma or GED | 1.202 | 0.524 | |

| Some college completed | 1.278 | 0.536 | |

| Associates or technical degree | 1.780 | 0.570 | |

| Bachelor's degree | 2.395 | 0.533 | |

| Postgraduate or greater | 4.128 | 0.540 | |

| Gender | Female | 0.886 | 0.173 |

| Income | Less than $25,000/year | ||

| $25,000–$50,000/year | 1.799 | 0.273 | |

| $50,000–$75,000/year | 1.951 | 0.288 | |

| $75,000–$100,000/year | 1.556 | 0.337 | |

| Greater than $100,000/year | 3.324 | 0.282 | |

| Political affiliation | Republican | ||

| Democrat | 0.878 | 0.249 | |

| Independent | 1.401 | 0.247 | |

| Progressive | 1.828 | 0.455 | |

| Not politically affiliated | 0.753 | 0.253 | |

| Location | Chittenden County | 0.815 | 0.190 |

| Year | 2020 | 3.587 | 0.166 |

| Constant | 137.135 | 0.657 |

Results from the LRTs for familiarity with hemp CBD oil, hemp clothing, and hemp paper lead us to fail to reject all null hypotheses. The influence of demographic variables on familiarity with hemp CBD oil ( χ 2 (16) = 20.095, p = 0.220), hemp clothing ( χ 2 (16) = 11.300, p = 0.790), and hemp paper ( χ 2 (16) = 12.058, p = 0.740) did not significantly change over time. Results of the logistic regressions of the restricted models for familiarity with each hemp product were significantly associated with year, with respondents being 3.909 ( p < 0.001), 2.824 ( p < 0.001), and 2.408 ( p < 0.001) times more likely to be familiar with hemp CBD oil, hemp clothing, and hemp paper, respectively (Table 5 ). Demographics had inconsistent significant associations with familiarity across specific hemp-based products. Older respondents are 0.960 ( p < 0.001), 0.975 ( p < 0.001), and 0.965 ( p < 0.001) percentage points less likely to be familiar with hemp CBD oil, hemp clothing, and hemp paper, respectively, than younger respondents. Education is significantly associated with familiarity with hemp clothing: those with a bachelor's degree or a postgraduate degree or greater are 3.783 ( p = 0.010) and 4.892 ( p = 0.003) times more likely to be familiar with hemp clothing than those with less than a high school diploma. Females are less likely to be familiar with hemp paper than males by 0.677 percentage points ( p = 0.008). Those with an income between $25,000 and $50.000 per year are 2.355 ( p = 0.017) times more likely to be familiar with hemp CBD oil than those with an income of less than $25,000 per year. Respondents with an income higher than $100,000 per year were 2.559 ( p = 0.020) and 1.938 ( p = 0.036) times more likely to be familiar with hemp CBD oil and hemp clothing, respectively. Respondents who identified as Progressives were 2.002 ( p = 0.030) times more likely to be familiar with hemp paper than Republican respondents.

| Variable | Definition | Hemp CBD oil | Hemp clothing | Hemp paper | |||

|---|---|---|---|---|---|---|---|

| Exp ( ) | SE | Exp ( ) | SE | Exp ( ) | SE | ||

| Age | Continuous | 0.960 | 0.009 | 0.975 | 0.006 | 0.965 | 0.005 |

| Education | Less than high school diploma | ||||||

| High school diploma or GED | 1.168 | 0.657 | 1.599 | 0.500 | 0.996 | 0.504 | |

| Some college completed | 1.201 | 0.666 | 2.382 | 0.512 | 1.782 | 0.508 | |

| Associates or technical degree | 2.106 | 0.745 | 2.502 | 0.549 | 0.924 | 0.532 | |

| Bachelor's degree | 1.912 | 0.675 | 3.783 | 0.515 | 1.200 | 0.502 | |

| Postgraduate or greater | 2.128 | 0.697 | 4.892 | 0.536 | 1.148 | 0.510 | |

| Gender | Female | 0.989 | 0.244 | 1.228 | 0.190 | 0.677 | 0.148 |

| Income | Less than $25,000/year | ||||||

| $25,000–$50,000/year | 2.355 | 0.359 | 1.543 | 0.287 | 0.785 | 0.253 | |

| $50,000–$75,000/year | 1.662 | 0.352 | 1.352 | 0.293 | 0.841 | 0.259 | |

| $75,000–$100,000/year | 1.675 | 0.411 | 1.623 | 0.342 | 0.763 | 0.281 | |

| Greater than $100,000/year | 2.559 | 0.403 | 1.938 | 0.316 | 0.655 | 0.257 | |

| Political affiliation | Republican | ||||||

| Democrat | 1.371 | 0.343 | 1.097 | 0.279 | 0.935 | 0.229 | |

| Independent | 1.565 | 0.338 | 1.439 | 0.276 | 1.287 | 0.223 | |

| Progressive | 3.603 | 0.675 | 2.047 | 0.475 | 2.002 | 0.319 | |

| Not politically affiliated | 1.064 | 0.379 | 0.792 | 0.295 | 0.611 | 0.256 | |

| Location | Chittenden County | 1.001 | 0.275 | 0.960 | 0.216 | 0.966 | 0.165 |

| Year | 2020 | 3.909 | 0.287 | 2.824 | 0.201 | 2.408 | 0.143 |

| Constant | 17.993 | 0.921 | 2.566 | 0.665 | 6.155 | 0.606 | |

Likelihood ratio test results for general use of hemp-based products lead us to fail to reject the null hypothesis that the influence of demographic variables on general use did not significantly change over time ( χ 2 (16) = 15.322, p = 0.500). Logistic regression results for the restricted model reveal that year is a statistically significant predictor of general use of hemp products ( p < 0.001; Table 6 ). Two categories of demographic variables are significant predictors of general hemp use: respondents with an Independent and a Progressive political orientation are 1.861 ( p = 0.005) and 2.640 ( p = 0.002) times more likely to use hemp products, respectively, than Republican respondents.

| Variable | Definition | General use | Hemp CBD oil | Hemp clothing | |||

|---|---|---|---|---|---|---|---|

| Exp ( ) | SE | Exp ( ) | SE | Exp ( ) | SE | ||

| Age | Continuous | 0.992 | 0.005 | 0.995 | 0.005 | 0.988 | 0.006 |

| Education | Less than high school diploma | ||||||

| High school diploma or GED | 0.600 | 0.474 | 1.272 | 0.606 | 0.595 | 0.627 | |

| Some college completed | 0.895 | 0.476 | 1.354 | 0.606 | 0.518 | 0.632 | |

| Associates or technical degree | 0.823 | 0.503 | 1.466 | 0.631 | 0.429 | 0.681 | |

| Bachelor's degree | 0.789 | 0.471 | 1.284 | 0.599 | 0.616 | 0.614 | |

| Postgraduate or greater | 0.738 | 0.480 | 0.920 | 0.609 | 0.710 | 0.623 | |

| Gender | Female | 1.165 | 0.146 | 1.148 | 0.166 | 1.245 | 0.194 |

| Income | Less than $25,000/year | ||||||

| $25,000–$50,000/year | 0.690 | 0.248 | 1.150 | 0.290 | 0.907 | 0.365 | |

| $50,000–$75,000/year | 1.015 | 0.252 | 1.470 | 0.293 | 1.734 | 0.350 | |

| $75,000–$100,000/year | 1.063 | 0.274 | 1.356 | 0.319 | 1.639 | 0.376 | |

| Greater than $100,000/year | 0.873 | 0.251 | 1.254 | 0.294 | 1.353 | 0.352 | |

| Political affiliation | Republican | ||||||

| Democrat | 1.278 | 0.228 | 1.373 | 0.268 | 1.700 | 0.344 | |

| Independent | 1.861 | 0.221 | 1.746 | 0.257 | 2.485 | 0.330 | |

| Progressive | 2.640 | 0.312 | 2.236 | 0.342 | 3.445 | 0.405 | |

| Not politically affiliated | 1.191 | 0.252 | 0.842 | 0.307 | 1.033 | 0.396 | |

| Location | Chittenden County | 1.015 | 0.161 | 1.317 | 0.179 | 1.057 | 0.210 |

| Year | 2020 | 2.295 | 0.140 | 2.884 | 0.162 | 3.103 | 0.192 |

| Constant | 0.779 | 0.577 | 0.108 | 0.724 | 0.129 | 0.787 | |

We also reject the null hypothesis that the influence of sociodemographic variables on use of both hemp CBD oil ( χ 2 (16) = 7.217, p = 0.970) and hemp clothing ( χ 2 (16) = 21.058, p = 0.180) did not significantly change between 2019 and 2020. Logistic regression results for the restricted models for use of hemp CBD oil and hemp clothing were both significantly associated with year, with respondents being 2.884 ( p < 0.001) and 2.103 ( p < 0.001) times more likely to use these products in 2020 compared to 2019 (Table 6 ). For use of hemp CBD oil, respondents with an Independent political orientation were 1.746 times more likely to use hemp CBD oil compared to Republican respondents. For use of hemp clothing, respondents with Progressive and Independent political orientations were 2.485 ( p = 0.006) and 3.445 ( p = 0.002) times more likely to use hemp clothing, respectively.

4 DISCUSSION

Hemp has been reintroduced to the production and market landscapes of the United States. Registered acreage is growing, processors are investing, and more innovative products are being researched and becoming accessible to consumers. Hemp has been touted as a sustainable and environmentally friendly crop, with thousands of potential products. However, the time and attention given to hemp have not been accompanied by evidence-based, peer-reviewed research on consumer segmentation and demand for hemp-based products. Now that hemp has been federally legalized and theoretical limitations, such as price volatility, oversupply, and risk management, are now experienced challenges, such information is critical to inform production and marketing strategies to enable a robust and resilient sector. Through a case study of Vermont residents, results offer a reference for consumer response and behavior toward hemp in the first year of federal legalization.

Results reveal that the association between demographic characteristics and support, awareness, and use of hemp and hemp-based products has not significantly changed over time. However, significant associations with demographic variables and support, awareness, and use exist across both survey years. Those with higher incomes were more likely to support hemp production than those in the lowest income bracket. This may be reflective of a “not in my backyard” mentality, where those with higher incomes are able to avoid proximity to hemp fields due to odor or drug-related concerns, while lower income households may not have that ability (Németh & Ross, 2014 ). Those in the highest income bracket were also more likely to be generally familiar with hemp products. This may support previous studies that find income is positively associated with hemp purchases, indicating that hemp-based products are more expensive compared to conventional products (Kim & Mark, 2018 ). Use is not significantly associated with income and may indicate that there is a more complex relationship with hemp consumption and demographic variables. When compared to other industry data, this study supports findings regarding high consumer awareness of CBD products (New Frontier Data, 2020b ). This study does not support industry findings that gender is a significant predictor of hemp CBD use (New Frontier Data, 2020a ).

Independent, Progressive, and Democrat respondents were more likely to support hemp production than Republican respondents. Progressive and Independent respondents were also more likely to be general users of hemp-based products, as well as users of hemp clothing. Independent political orientation was associated with use of hemp CBD oil. These results support findings in a 2019 case study of Vermont residents, and further demonstrate continued political polarization of hemp due to the stigma related to drugs and marijuana (Kolodinsky et al., 2020 ). Public education on hemp's unique traits and distinction from marijuana may help to build confidence in consumers unwilling to try hemp-based products due to this false stigma. Age was the only consistent demographic predictor of hemp familiarity, both generally and with hemp CBD oil, hemp clothing, and hemp paper. Older respondents are less likely to be familiar with these products than younger respondents. This points to segmented education opportunities to broaden knowledge of hemp products in order to grow their accessibility and use in the market.

Noteworthy is the finding that respondents were more likely to be general users of hemp, as well as specific users of hemp CBD oil and hemp clothing in 2020 compared to 2019. This could be the result of the widespread introduction and adoption of hemp-based products into the market. However, this may also be due to differences in recall strategy between survey years, where the 2020 survey provides a list of hemp products based on responses to the open-ended 2019 survey. These recall differences are a limitation of this study.

This study finds that awareness and use of hemp-based products among Vermont respondents have experienced structural change over time in its first 2 years of federal approval. Although demographic variables did not significantly change over time, we find political affiliation to be a significant predictor of hemp use. Remaining demographic characteristics were found to be inconsistent predictors of hemp familiarity and use. These findings support previous research and contribute to the indication that consumer preference for hemp-based products may be influenced by attitudes and opinions (Kolodinsky et al., 2020 ). Future research should include information on consumer motivations for purchasing hemp products that go beyond demographic characteristics and reach a sample wider than a single state. USDA grant 2020-67024-30955- Economic Impacts of the Hemp Industry: Opportunities for Rural Development provides funding to conduct a national consumer study in 2021. Recommendations derived from this study will be contributed to the creation of the survey.

Open Research

Data availability statement.

The data that support the findings of this study are available from the corresponding author upon reasonable request.

- Agriculture Improvement Act of 2018 . (2018). S. 3042 , 115th Congress. Google Scholar

- Agricultural Act of 2014 . (2014). H.R. 2642 , 113th Congress. Google Scholar

- Amaducci, S. , Scordia, D. , Liu, F. H. , Zhang, Q. , Guo, H. , Testa, G. , & Cosentino, S. L. ( 2015 ). Key cultivation techniques for hemp in Europe and China . Industrial Crops and Products , 68 , 2 – 16 . https://doi.org/10.1016/j.indcrop.2014.06.041 10.1016/j.indcrop.2014.06.041 CAS Web of Science® Google Scholar

- Das, L. , Liu, E. , Saeed, A. , Williams, D. W. , Hu, H. , Li, C. , Ray, A. E. , & Shi, J. ( 2017 ). Industrial hemp as a potential bioenergy crop in comparison with kenaf, switchgrass and biomass sorghum . Bioresource Technology , 244 ( August ), 641 – 649 . https://doi.org/10.1016/j.biortech.2017.08.008 10.1016/j.biortech.2017.08.008 CAS PubMed Web of Science® Google Scholar

- Ellison, S. ( 2020 ). National hemp research needs survey results 2020 . National Hemp Research and Education Virtual Conference . Colorado State University. Google Scholar

- Finnan, J. , & Styles, D. ( 2013 ). Hemp: A more sustainable annual energy crop for climate and energy policy . Energy Policy , 58 , 152 – 162 . https://doi.org/10.1016/j.enpol.2013.02.046 10.1016/j.enpol.2013.02.046 Web of Science® Google Scholar

- Greene, W. H. ( 2012 ). Tests and restrictions in models for binary choice . In Econometric modeling guide ( 10th ed. , pp. E578 – E588 ). Econometric Software Inc. Google Scholar

- Kim, G. , & Mark, T. ( 2018 ). Who are consuming hemp products in the U.S.? Evidence from Nielsen Homescan data . SSRN Electronic Journal , 1 – 28 . https://doi.org/10.2139/ssrn.3176016 Google Scholar

- Kolodinsky, J. , Lacasse, H. , & Gallagher, K. ( 2020 ). Making hemp choices: Evidence from Vermont . Sustainability , 12 ( 15 ), 6287 . https://doi.org/10.3390/su12156287 10.3390/su12156287 Web of Science® Google Scholar

- Langeveld, J. W. A. , Dixon, J. , & Jaworski, J. F. ( 2010 ). Development perspectives of the biobased economy: A review . Crop Science , 50 ( April ), S-142 – S-151 . https://doi.org/10.2135/cropsci2009.09.0529 10.2135/cropsci2009.09.0529 Google Scholar

- Leas, E. C. , Nobles, A. L. , Caputi, T. L. , Dredze, M. , Smith, D. M. , & Ayers, J. W. ( 2019 ). Trends in internet searches for Cannabidiol (CBD) in the United States . JAMA Network Open , 2 ( 10 ), 1 – 4 . https://doi.org/10.1001/jamanetworkopen.2019.13853 10.1001/jamanetworkopen.2019.13853 Web of Science® Google Scholar

- Malone, T. , & Gomez, K. ( 2019 ). Hemp in the United States: A case study of regulatory path dependence . Applied Economic Perspectives and Policy , 41 ( 2 ), 199 – 214 . https://doi.org/10.1093/aepp/ppz001 10.1093/aepp/ppz001 Web of Science® Google Scholar

- Mark, T. ( 2020 ). Economics and marketing overview . National Hemp Research & Education Virtual Conference . Colorado State University. Google Scholar

- Mark, T. , Shepherd, J. , Olson, D. , Snell, W. , Proper, S. , & Thornsbury, S. ( 2020 ). Economic viability of industrial hemp in the United States: A review of state pilot programs . United States Department of Agriculture. Retrieved from https://www.ers.usda.gov/webdocs/publications/95930/eib-217.pdf Google Scholar

- Mark, T. B. , & Snell, W. ( 2019 ). Economic issues and perspectives for industrial hemp . In D. Williams (Ed.), Industrial hemp as a modern commodity crop (pp. 107 – 118 ). John Wiley & Sons. 10.2134/industrialhemp.c7 Google Scholar

- McCallum, K. ( 2019 , January 2). Sow much hemp: A large harvest prompts fears of oversupply . Seven Days . https://www.sevendaysvt.com/vermont/sow-much-hemp-a-large-harvest-prompts-fears-of-oversupply/Content?oid=28809755 Google Scholar

- McCormick, K. , & Kautto, N. ( 2013 ). The bioeconomy in Europe: An overview . Sustainability (Switzerland) , 5 ( 6 ), 2589 – 2608 . https://doi.org/10.3390/su5062589 10.3390/su5062589 Web of Science® Google Scholar

- Németh, J. , & Ross, E. ( 2014 ). Planning for marijuana: The cannabis conundrum . Journal of the American Planning Association , 80 ( 1 ), 6 – 20 . https://doi.org/10.1080/01944363.2014.935241 10.1080/01944363.2014.935241 Web of Science® Google Scholar

- New Frontier Data . ( 2020a ). Frequency of use among U.S. CBD consumers . Retrieved from https://newfrontierdata.com/cannabis-insights/frequency-of-use-among-u-s-cbd-consumers/ Google Scholar

- New Frontier Data . ( 2020b ). U.S. consumer report series: Spending & market size . Retrieved from https://f.hubspotusercontent10.net/hubfs/3324860/ExecSummaries/NFD-USCBDConsumerReport-Vol2-ES.pdf?utm_campaign=U.S.CBDReport%3AMarketSize%26Demand&utm_medium=email&_hsmi=96209094&_hsenc=p2ANqtz-_cYuXJdxLseSHdL7jfd0MvxCl4LoyRZIW_p5iKLvuHInHgTkfpvYj Google Scholar

- Papadopoulou, E. , Bikiaris, D. , Chrysafis, K. , Wladyka-Przybylak, M. , Wesolek, D. , Mankowski, J. , Kolodziej, J. , Baraniecki, P. , Bujnowicz, K. , & Gronberg, V. ( 2015 ). Value-added industrial products from bast fiber crops . Industrial Crops and Products , 68 , 116 – 125 . https://doi.org/10.1016/j.indcrop.2014.10.028 10.1016/j.indcrop.2014.10.028 CAS Web of Science® Google Scholar

- Popular Mechanics Magazine . ( 1938 ). Billion-dollar crop (Vol. 69 , Issue 2 ). Hearst Magazines. Google Scholar

- Rehman, M. S. U. , Rashid, N. , Saif, A. , Mahmood, T. , & Han, J. I. ( 2013 ). Potential of bioenergy production from industrial hemp ( Cannabis sativa ): Pakistan perspective . Renewable and Sustainable Energy Reviews , 18 , 154 – 164 . https://doi.org/10.1016/j.rser.2012.10.019 10.1016/j.rser.2012.10.019 Web of Science® Google Scholar

- Tang, K. , Struik, P. C. , Amaducci, S. , Stomph, T. J. , & Yin, X. ( 2017 ). Hemp ( Cannabis sativa L.) leaf photosynthesis in relation to nitrogen content and temperature: Implications for hemp as a bio-economically sustainable crop . GCB Bioenergy , 9 ( 10 ), 1573 – 1587 . https://doi.org/10.1111/gcbb.12451 10.1111/gcbb.12451 CAS Web of Science® Google Scholar

- United States Census Bureau . ( 2019 ). QuickFacts: Vermont . Retrieved from https://www.census.gov/quickfacts/VT Google Scholar

- Vermont Agency of Agriculture Food and Markets . ( 2019 ). Hemp Program . Retrieved from https://agriculture.vermont.gov/public-health-agricultural-resource-management-division/hemp-program Google Scholar

- Vermont Department of Health . ( 2019 ). Population of Vermont by county, age and sex, 2000–2018 . Vermont Department of Health. Google Scholar

- Vote Hemp . (n.d.). U.S. hemp crop report . Vote Hemp. Retrieved from https://www.votehemp.com/u-s-hemp-crop-report/ Google Scholar

- Wallace Allen, A. ( 2019 , January 2). Making it in Vermont: Hemp producers ready to grow . Vtdigger. Retrieved from https://vtdigger.org/2019/01/20/making-vermont-hemp-producers-ready-grow/ Google Scholar

Citing Literature

Volume 13 , Issue 4

Pages 537-545

Information

The full text of this article hosted at iucr.org is unavailable due to technical difficulties.

Log in to Wiley Online Library

Change password, your password must have 10 characters or more:.

- a lower case character,

- an upper case character,

- a special character

Password Changed Successfully

Your password has been changed

Create a new account

Forgot your password.

Enter your email address below.

Please check your email for instructions on resetting your password. If you do not receive an email within 10 minutes, your email address may not be registered, and you may need to create a new Wiley Online Library account.

Request Username

Can't sign in? Forgot your username?

Enter your email address below and we will send you your username

If the address matches an existing account you will receive an email with instructions to retrieve your username

- DOI: 10.1093/AEPP/PPZ001

- Corpus ID: 159385994

Hemp in the United States: A Case Study of Regulatory Path Dependence

- Trey Malone , Kevin D. Gomez

- Published in Applied Economic Perspectives… 1 June 2019

- Law, Medicine, Political Science

- Applied Economic Perspectives and Policy

Figures and Tables from this paper

30 Citations

The reintroduction of hemp in the usa: a content analysis of state and tribal hemp production plans, consumer response to hemp: a case study of vermont residents from 2019 to 2020, is the emerging u.s. hemp industry yet another boom–bust market for u.s. farmers, a review on the current state of knowledge of growing conditions, agronomic soil health practices and utilities of hemp in the united states.

- Highly Influenced

Modeling hemp as an innovative input: an application of the diffusion of innovations in a sample of hemp aware consumers

Concern and externalities associated with locating hemp production and processing facilities, industrial hemp knowledge and interest among north carolina organic farmers in the united states, hemp agronomy: current advances, questions, challenges, and opportunities, uncovering the secrets of industrial hemp in food and nutrition: the trends, challenges, and new-age perspectives, a critical analysis of hemp (cannabis sativa l.) use: scientific, legislative and socio-economic aspects, 73 references, industrial hemp in north america: production, politics and potential.

- Highly Influential

Industrial hemp (Cannabis sativa L): The geography of a controversial plant

Opportunities for commercial hemp production, challenges towards revitalizing hemp: a multifaceted crop., industrial hemp as a potential bioenergy crop in comparison with kenaf, switchgrass and biomass sorghum., hemp: a more sustainable annual energy crop for climate and energy policy, effects of the national bioengineered food disclosure standard: willingness to pay for labels that communicate the presence or absence of genetic modification, the cannabinoid content of legal cannabis in washington state varies systematically across testing facilities and popular consumer products, cannabidiol (cbd) and its analogs: a review of their effects on inflammation., energy and environmental assessment of industrial hemp for building applications: a review, related papers.

Showing 1 through 3 of 0 Related Papers

Below is a list of free resources to download.

Education FREE PDF

Download information leaflets for educational purposes: IHBA information brochure PDF.

IHBA information leaflet PDF.

Welcome. Click on the button or image to read and download the IHBA Position Paper from February 2022 on The Appropriate Measurement of Hemp and Other Natural Building Material Performance.

Other resources on hemp building.

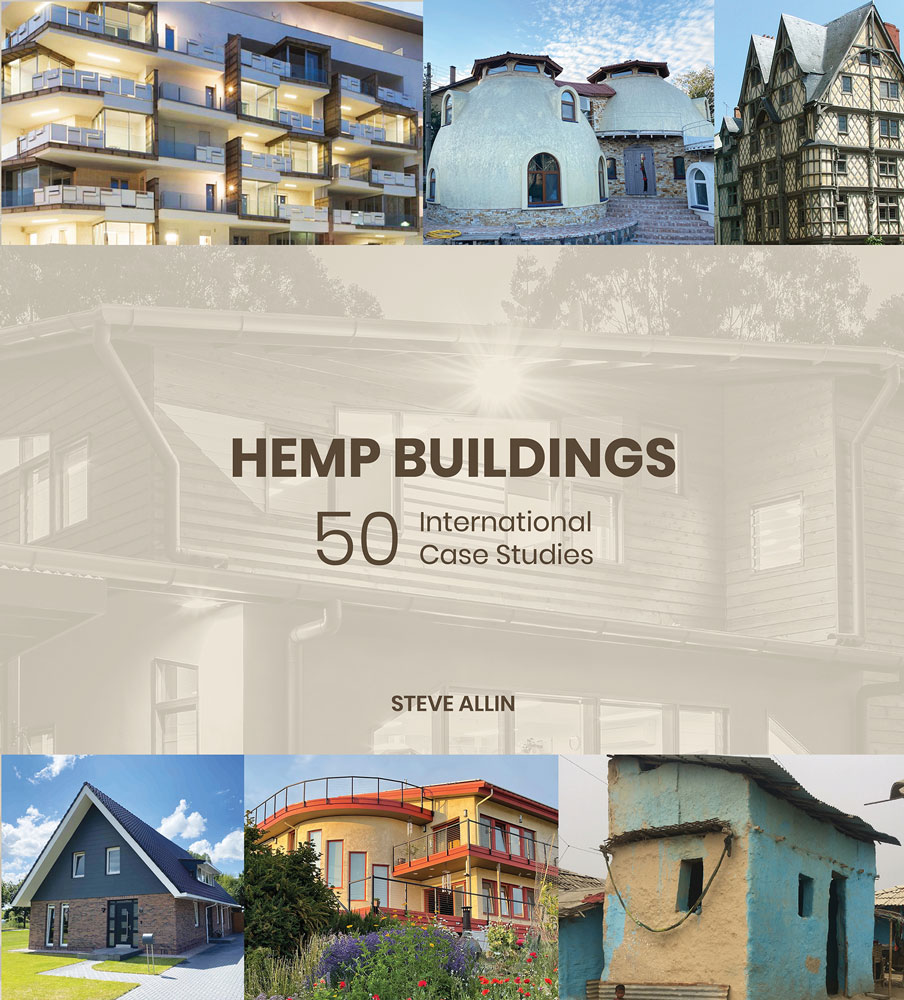

Hemp Buildings: 50 International Case Studies

by Steve Allin, order the book from the Seedpress website. 2022

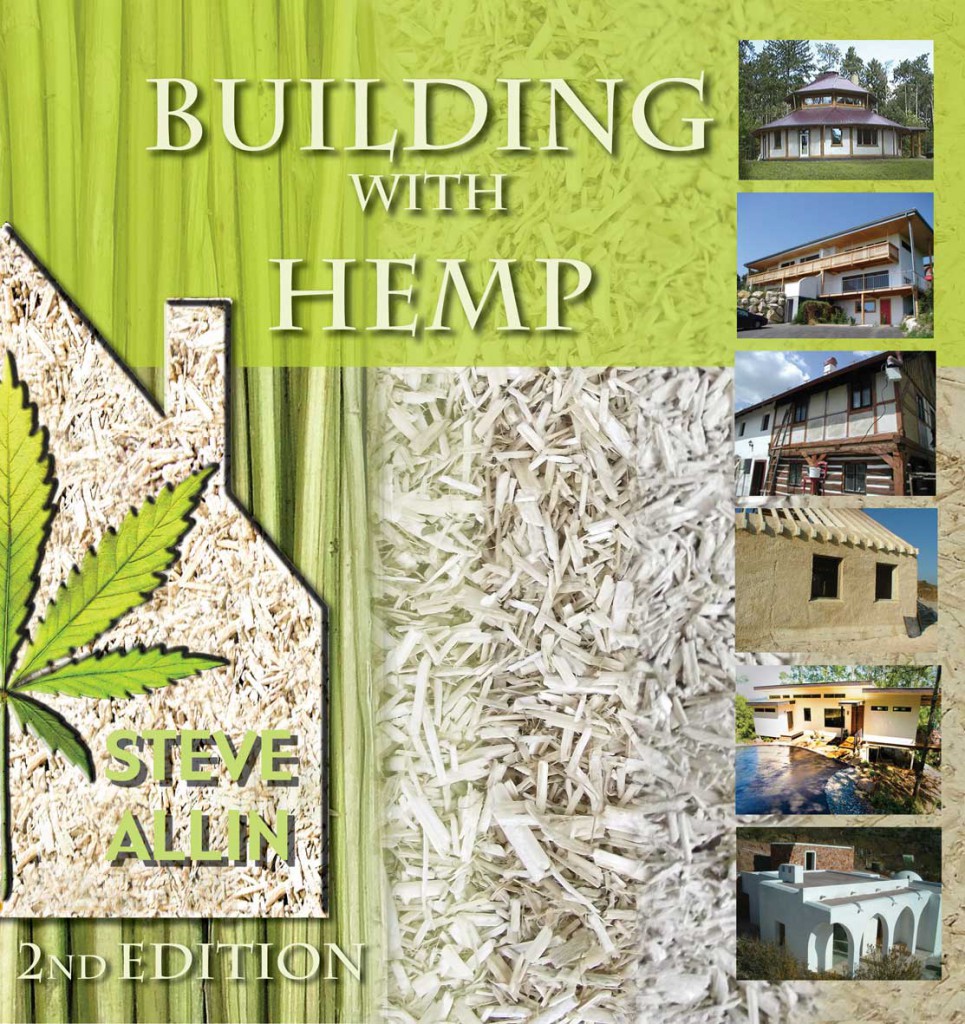

Building with Hemp – original English language edition

by Steve Allin, order the book from the Seedpress website. 2012

Construire en Chanvre – Edition Française

par Steve Allin, version eBook de l’ouvrage de référence sur le système révolutionnaire de construction en chanvre. 2023

ÉPÍTSÜNK KENDERREL! – Hungarian language edition

Steve Allin nagy sikerű könyvének magyar nyelvű kiadása. 2022

This is content only available to IHBA Members

Hemp Building Best Practice Guide ebook PDF.

Available to Members Only . Produced by the International Hemp Building Association (IHBA) for guidance to those involved in building and building design.

Presentations

Past presentations from IHBA symposiums.

Available to Members Only . Produced by the International Hemp Building Association (IHBA) over 150 past presentations consisting of PDF and Video files, from the IHBA symposiums held globally since 2009.

Remember me

Forgot Password?

By continuing to use the site, you agree to the use of cookies. more information Accept

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.

Title: Marketing potentials of ecofriendly paper products: case study

Authors : Alan D. Smith

Addresses : Department of Marketing, Robert Morris University, 6001 University Blvd, Moon Twp, PA 15108, USA

Abstract : The ecofriendly or green revolution has greatly evolved, especially from a marketing perspective. Hemp products, especially food protein and non-food products (paper) may well be the next evolution ecofriendly supply chain strategies. Through the use of a case study approach, hemp as a source for paper that results in a quicker cycle time and is more climate change friendly than trees, may well turn out to be a part of a sustainable supply chains. Besides the direct environmental impact, paper pulp requires a number of chemical treatments in order for it to have longevity as a product. The innovative solution that can challenge the traditional monopoly is hemp-based, ecofriendly paper products. Hemp paper is a natural alternative to tree-based paper and is an obvious upgrade from the latter. Recent federal degradations have made this ecofriendly resource extremely attractive.

Keywords : cash crops; hemp paper; ecofriendly; green products; supply chain management; SCM; sustainable supply chain integration; SSCI; sustainability.

DOI : 10.1504/IJBFMI.2023.129853

International Journal of Business Forecasting and Marketing Intelligence, 2023 Vol.8 No.2, pp.157 - 178

Received: 20 Jul 2022 Accepted: 26 Jul 2022 Published online: 31 Mar 2023 *

Keep up-to-date

- Our Newsletter ( subscribe for free )

- New issue alerts

- Inderscience is a member of publishing organisations including:

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Materials (Basel)

Hemp and Its Derivatives as a Universal Industrial Raw Material (with Particular Emphasis on the Polymer Industry)—A Review

Associated data.

No data are available while the first author was a doctoral candidate in the Interdisciplinary Doctoral School at the Lodz University of Technology, Poland.

This review article provides basic information about cannabis, its structure, and its impact on human development at the turn of the century. It also contains a brief description of the cultivation and application of these plants in the basic branches of the economy. This overview is also a comprehensive collection of information on the chemical composition of individual cannabis derivatives. It contains the characteristics of the chemical composition as well as the physicochemical and mechanical properties of hemp fibers, oil, extracts and wax, which is unique compared to other review articles. As one of the few articles, it approaches the topic in a holistic and evolutionary way, moving through the plant’s life cycle. Its important element is examples of the use of hemp derivatives in polymer composites based on thermoplastics, elastomers and duroplasts and the influence of these additives on their properties, which cannot be found in other review articles on this subject. It indicates possible directions for further technological development, with particular emphasis on the pro-ecological aspects of these plants. It indicates the gaps and possible research directions in basic knowledge on the use of hemp in elastomers.

1. Introduction

The polymer industry has grown smoothly and continuously for many decades. Polymers and composites based on them have become one of the basic utility materials, next to wood, concrete, glass or metals, for the production of simple everyday objects, through elements of larger structures, such as vehicles and buildings, to modern and very complex parts, specialized equipment and even spaceships. The wide range of polymers and their properties, which can be further changed by the use of other materials and ingredients, give us as scientists an infinite field for the development of these versatile materials, limited only by our imagination. All this makes polymer composites a versatile product. However, they have their pros and cons, as with any other product. One such ambiguous property is its high durability. As consumers, we most often want polymer materials to have as much as possible, but after use, a problem arises. What to do with such materials? Unfortunately, many of the plastics used so far do not break down too quickly [ 1 ]. For some of them, this process can take hundreds of years. For this reason, the growing awareness of researchers, consumers and ecologists put pressure on the development of the field of science dealing with polymer materials and biocomposites, which, in particular, should be characterized by a high biodegradability or compostability potential [ 2 , 3 , 4 , 5 ]. One of the approaches to the development of environmentally friendly polymer materials is the use of substances derived from fauna and flora in composites. An even better solution is to use materials that are typical production waste from other industrial sectors. In this article, we focus on presenting just such an approach. This review focuses on the material of plant origin, and in particular on hemp and all its derivatives that have or may have potential industrial applications, including with particular emphasis on polymers for the creation of biocomposites.